In brief

- Industrial-grade mobile apps and rugged handheld units are making it possible to manage and control the maintenance function from remote locations.

- Mobile phones are replacing Internet connections on the plant floor.

- Designs and plant policies might limit the extent to which wireless technology can be implemented in the plant.

Surging interest in industrial mobility can be credited to the confluence of trendy device choices, lower-cost connectivity and tech-savvy “Millennials” — children of Baby Boomers, also known as Generation Y — now entering the workforce. Applications (apps) to foster operations and maintenance efficiency abound for both rugged and consumer-grade wireless technologies, but getting the highest return on your mobility investment requires matching the strategy to your particular environment.

Early adopters lead the way

Rugged devices were the first to hit the plant floor. Soft dB, a manufacturer of acoustical equipment, chose DAP Technologies’ M8910 rugged tablet computer for acoustic and vibration measurement. “It allows us to be an innovator by integrating signal technology into a modern tablet PC,” says André L'Espérance, president of Soft dB (www.softdb.com) in Quebec City, Quebec. “Once it’s fully deployed, we expect that hundreds of users will be using the device.”

Figure 1. The FLIR Viewer App lets you send thermal images directly to your iPad and email it right away.

Coatings and specialty products manufacturer PPG Industries uses Motorola’s MC9000 rugged handheld mobile computers for mobile human-machine interface (HMI) and asset management, and private commercial radios from Motorola to improve plant communications and security. “Although we’re just in the infancy of enabling the mobile operator and technician in our facility, the potential benefits in efficiency, safety and environment are huge,” says Rob Brooks, process control supervisor for PPG Industries (www.ppg.com) in Pittsburgh.

The new wave in mobility is smart apps. One wholesale craft beer brewery is pilot testing Aurora Mobile Apps from Aurora Industrial Automation to access its Rockwell Automation FactoryTalk visualization system from any location. With an Apple iPad or iPhone, users can monitor and compare the processes, such as the status of the brewer’s mash filtration system, in real time.

Vendor offerings are many and varied

Figure 2. With an iPhone, you can carry every FLIR IR picture ever taken anywhere you go.

The Flir Viewer App, released earlier this year, lets you send thermal images and data from a Flir E-Series or T-Series camera directly to your iPhone, iPad or iPod touch without connecting cables or swapping SD cards. “With this app, when you snap a picture of a problem with your Flir camera, you can call it up on your iPhone via Wi-Fi from the floor and email it to any number of recipients right away,” says Ed Kochanek, director of sales, eastern region, for Flir Systems (www.flir.com). “The app (Figure 1) is generating great excitement with our customers. With an iPhone or iPad, it’s easier to store, scroll through, analyze and share pictures. It allows you to carry every picture ever taken anywhere you go (Figure 2).”

The ProSoft i-View, launched in 2010, is a mobile app for Apple devices that enables remote process monitoring and control with real-time process data. “If you need to know immediately when there’s a fault in a line valve, or a motor seizes, or a drive stops working, the i-View can detect it,” says Chris Hines, training manager for ProSoft Technology (www.prosoft-technology.com). “We recognized the inevitability of melding between consumer and industrial technologies via mobile apps. So, we began investigating opportunities to leverage these tools to complement our solutions and our customers’ applications.”

{pb}The SKF Microlog Inspector System simplifies data collection and remote data transfer for condition monitoring, inspections, safety and maintenance. It runs on Windows Mobile 6.1 devices, allowing customers to use their existing handheld devices if desired. It can connect automatically and wirelessly to a central server using a LAN, Wi-Fi or 3G/GPRS cellular data network (Figure 3).

Figure 3. The SKF Microlog Inspector System simplifies data collection and remote data transfer for condition monitoring, inspections, safety and maintenance.

Trial apps are good for gauging interest. “At last year's Automation Fair, we used iPads in the booth to display live data from three flow instruments using an app developed specifically for demonstration at the show,” says Jeremy Farrow, marketing communications manager for Endress+Hauser (www.us.endress.com). “Customers thought it was great and now we have to figure out how we can turn it into something more.”

When vendor support is needed, mobility has its advantages. Rockwell Automation customers can access the support center from a smartphone. “Previously, you needed an Internet connection and now all you need is a phone connection,” says Jon Furniss, product manager for remote support at Rockwell Automation (www.rockwellautomation.com). There’s no application to download. The system recognizes from the IP address when the user is connecting with a smartphone, tablet or other mobile device and automatically presents the small-screen user interface with the same capabilities as a traditional connection.

Mobile apps are equally beneficial to maintenance service providers. Rockwell Automation’s installed base evaluation (IBE) service for strategic maintenance is faster because of its partnership with Meridium. “We collect information from the customer’s site, analyze it and provide recommendations on how to optimize MRO in their facilities and manage obsolescence risk,” says Jessica Korpela, Rockwell Automation product manager for installed base evaluations. Meridium’s tablet application framework allows the maintenance data to be synchronized in real time. “Using tablets for data collection allows IBEs to be done in half the time,” adds Korpela. The program currently supports Dell-branded tablets (Figure 4).

Figure 4. Meridium’s tablet application framework allows maintenance data to be synchronized in real time.

New apps are emerging

At least three companies are pilot testing Aurora Mobile Apps, the new Apple iPad/iPhone app from Aurora Industrial Automation. The app gives users real-time, read-only, remote access to plant floor data through certain Rockwell Automation FactoryTalk visualization systems using an Internet browser. It reportedly won’t be made available on the iTunes library until the iPad and comparable device security features are improved, and they’re hardened for industrial use.

Opto 22 (www.opto22.com) is considering mobile industrial control, monitoring and data acquisition options. “It’s true we’re in the process of developing mobile platforms for our SNAP PAC line. However, we’re quite a way off from having an actual application,” says David Crump, Opto 22’s marketing communications manager. “We do, however, recognize the fact that everyone's grown accustomed to having the ability to communicate, access information and exchange data from wherever they are. Automation professionals increasingly want to access real-time plant data on the go, so that they can monitor things like processes, energy usage and machine performance continuously.”

Further innovations are underway at Rockwell Automation’s support center. “We’re looking into having customers send SMS texts for technical support, and we’re investigating whether social media like Facebook and Twitter is a place for technical support,” says Furniss. “We’re currently testing the use of mobile video cameras so that when our engineers call with questions from the plant floor, we can see what they’re doing. And we’re investigating instant translations to convert online chat to the local language in real time automatically.”

Motivators for mobility

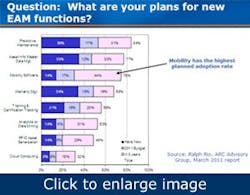

The appeal of mobility is catching. ARC Advisory Group (www.arcweb.com) Research Director Ralph Rio found high interest in mobility in his March 2011 survey of industrial maintenance, IT and executive professionals, “Survey Results for EAM Systems: Current Practices and Future Plans.” Of the respondents, representing more than 5,000 plants globally, three-quarters have already implemented mobility software for EAM functions or plan to do so within one to three years (Figure 5).

Figure 5. Mobility has the highest planned adoption rate.

Why so much interest? For one, because Millennials in the workforce grew up with computers and handheld devices, they expect them at work, explains June Ruby, manufacturing principal for the Motorola Solutions Industry Solutions Group (www.motorolasolutions.com). Additionally, the economy changed the manufacturing environment. “Demand and production is ramping up, but we’ve been left with a scaled-down workforce. We can’t afford to let people sit in a control room. The same person might need to perform safety rounds, quality inspections and track processes,” explains Ruby.

{pb}Practical benefits

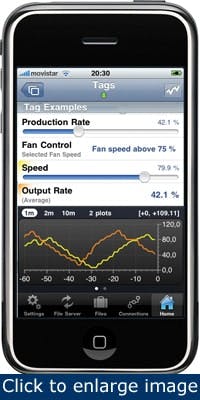

Figure 6. ProSoft i-View enables real-time remote process monitoring from your iPhone.

First and foremost, mobility drives visibility. “You don’t have to be sitting at a computer to see the data,” says ProSoft’s Hines. “With Wi-Fi, you can be anywhere in the plant. With a cellular network, you can be anywhere in the world. It gives executive management a view into the process, as well” (Figure 6)

With mobility, you eliminate the paper trail, adds Jerry Steenhoek, chief technologist/project manager for Interstates (www.interstates.com). “Instead of turning in a sheet of paper at the end of the day, when the information could be lost or misread, the data is entered once and is immediately accessible.”

The productivity potential is immense. “The impact of this newfound mobility on business processes will be significant, largely because a mobile workforce equals a more productive workforce,” says Opto 22’s Crump. “Mobile technology is doing what the laptop did for the office 20 years ago,” adds Scott Brady, senior manager of publications, portables and wireless at SKF Condition Monitoring Center (www.skf.com). “With mobility, you’re not tied to one spot. If you’re out in the plant or even hundreds of miles away, you have all the data that’s available in the office at your fingertips.”

Technology convergence extends the time savings and process automation benefits, explains ARC’s Rio. “Maintenance personnel can process their work orders during their rounds, rather than waiting until the end of the shift and risking errors or omissions. Using the phone's camera, a photograph of what’s broken can accompany the work order, and matching that image to the MRO catalog ensures the right spare part is picked. With Bluetooth instruments, thermal readings taken on inspection rounds are automatically in the system entered, avoiding typographical errors. With RFID, an asset’s serial number is entered in the work order automatically. And GPS capabilities enable routing optimization,” says Rio.

One of the biggest opportunities in mobility is adding discipline to standard processes, says Kevin Prouty, research director, for enterprise applications at Aberdeen Group (www.aberdeen.com). “Before, you might have suspected not every item was being inspected. Now, when inspections are performed using a mobile device with a bar code scanner, you know when steps are skipped. It enforces discipline in the process.” (Figure 7)

Figure 7. Mobility is a knowledge management enabler.

A role for consumer devices

Eric Miller, vice president of sales for DAP Technologies (www.daptech.com), recognizes that consumer devices are gaining in prominence. “It’s a result of the proliferation of mobile devices, such as smartphones and iPads, in consumer markets and our everyday lives,” he says. “It’s natural that business users want to leverage the tools that allow the seamless exchange of data wirelessly and ease of communication in enterprise settings.”

A large portion of the population has a smartphone, says Rio. “While the cost of rugged hardware has fallen substantially, some plants are starting to substitute them with smartphones,” he explains. “In some cases, a few broken smartphones cost less than one ruggedized device.”

{pb}Aberdeen’s Prouty agrees that companies are increasingly willing to try lower-cost, more-flexible consumer devices. “There’s been an explosion of capabilities in the newer, off-the-shelf, consumer-grade devices,” he says. “They’re eating a little market share from rugged devices, which aren’t keeping up with features and capabilities.” (Figure 8)

Figure 8. Where are best-in-class companies using rugged and consumer devices?

A notable iPad advantage is that its battery charge lasts much longer than most laptop batteries. Aurora observes that in an industrial setting, an iPad’s 10-hr charge could last a couple of days depending on usage.

Why rugged still rules

The main reasons that Soft dB decided to partner with DAP was the modularity and ruggedness of its computers. “It was one of the only tablet PCs that would allow for integration of our custom digital signal processor board, and DAP’s computers are rugged enough to be used in the field in all kinds of weather and conditions,” says L'Espérance.

“Anecdotally, we’ve heard that in warehouse and manufacturing operations, consumer-grade devices have limited capabilities for the ergonomics of automatic data collection; they’re not moisture- or dust-proof, and they can’t take significant drops,” observes Aberdeen’s Prouty.

Companies that ban camera devices for proprietary or classified reasons effectively eliminate most consumer-grade devices from consideration. Aurora would like to see additional security features in the consumer devices relative to user access control, usage tracking and feature lockdown.

Device price shouldn’t be a primary concern. “The perceived notion that a rugged tablet should cost the same as an iPad is a misconception,” says DAP’s Miller. “A consumer model might cost less up front, but it isn’t built for the challenges of field service or industrial use. The high failure rates for consumer models in these markets produce a domino effect of downtime, lost productivity, and increased repair and replacement costs.”

While industrial PDAs are taking on some cell phone characteristics, there’s still room for improvement. “You can get GPS built in and you can make phone calls on PDAs with a SIM card, but mostly they just capture data,” says SKF’s Brady. “There’s a need for more lightweight tablets that are easier to carry around than the big, bulky, industrial types available now.”

Motorola is glad people are exploring new ways to use mobility, including with consumer devices, says Ruby. “Enterprise-grade device manufacturers benefit from those experiences because the customers validate the use case,” she explains. “Most customers quickly realize that the reality of rolling out the mobile solution across an enterprise calls for an enterprise-grade device.”

Choose the right device

Before selecting a device, Motorola Solutions suggests exploring its use case. Will the device be assigned to someone or part of a shared collection? Will the environment have carpet or concrete floors, and is it a Class I or Class II hazardous area? Will the device access intellectual property, requiring data encryption and the ability to be wiped clean if it’s lost or stolen? Will IT have visibility to monitor and troubleshoot the device and access to push down security patches and upgrades? The total cost of ownership is another consideration. How long do you expect the devices to be in service before you do a refresh? If you’ve chosen cellular service, is one carrier enough or do you need multiple carriers for full, real-time coverage?

Figure 9. Because the Millennials in the workforce grew up with computers and handheld devices, they expect them at work.

“For some users, the right device is a two-way radio providing business critical voice communication,” explains Motorola’s Ruby. “Others might need a rugged mobile computer with a screen and keypad to access and update work orders and look up the equipment’s maintenance history.” (Figure 9)

SKF found that people in the industry tend to want to use their existing device investments. DAP suggests using computers like theirs that offer ruggedness to increase uptime and decrease maintenance costs, flexibility to increase productivity and consolidate the number of devices needed, and modularity so the computers to work the way the business needs them to work.

Consumer-grade device competition is growing fast. “While the iPad has a lot of mindshare, it probably won’t make it into the EAM space as much as some Android-based products will,” predicts ARC’s Rio. “Apple devices have their limitations and might lose favor to suitable Androids as they emerge. For instance, many in maintenance feel strongly about having a ‘real’ keypad with tactile feedback, not a virtual one. Gloves and fat fingers are a particular hindrance for Apple devices.”

Get the app right

Regardless of the device, the application’s user interface must fit the screen. Best-in-class companies are significantly more likely to customize and simplify the screens, according to the 2011 Aberdeen Group report, “Mobility in ERP 2011.” Shrinking a regular ERP screen to fit on a mobile device is one of the first reasons for users rejecting the system, says Aberdeen’s Prouty. “If you don’t have a screen you can use, the system will fail,” he explains.

{pb}“More EAM suppliers, such as IBM and Mincom, are offering pre-integrated mobile software applications,” says ARC’s Rio. “Others, including SAP and Oracle, have Web integration partnerships to ensure predictable, repeatable results.”

Don’t be intimidated by the infrastructure, cautions Prouty. “That’s one of the simpler parts,” he says. “The cost to implement and operate a wireless infrastructure has come down so far during the last five or six years.”

The emergence of mesh networks and intrinsically safe routers has lowered the cost of the Wi-Fi infrastructure, adds Rio. “In many cases, enlightened managers have made Wi-Fi part of the IT infrastructure, saving maintenance personnel from having to include the cost of a Wi-Fi network in their project proposals,” he says.

You don’t need an IT infrastructure if you have cell signals, says SKF’s Brady. “Cell phones are supporting faster and faster speeds, and now the data can be fed via GSM card, phone card or Mi-Fi — a mini-router that acts like a mobile Wi-Fi hot spot for cell phones,” he says. “It takes the question of how to connect out of the equation.”

Advanced communications options provide further benefits. “DAP is among the first to offer integrated ZigBee wireless technology, which is a low-power sensor technology, and wireless USB, which allows for the connection of multiple peripherals and the wireless transmission of data at speeds similar to a wired connection,” says DAP’s Miller (Figure 10).

Figure 10. Wireless USB allows for the wireless transmission of data at speeds similar to a wired connection.

Coincidentally, there’s an app for planning and managing wireless networks. The ProSoft RadioLinx Calculator, which runs on Android devices, as well as the iPhone and iPad, takes the entered radio and hardware variables and calculates the theoretical link signal strength between two sites so that adjustments to improve the link quality can be made.

If infrastructure isn’t your strong suit, SKF hosts software as a service (SaaS), helping customers to upload and download data from remote locations because they don’t have to worry about internal firewall security. With SaaS, the vendor takes over the installation, backups and now the mobile connectivity.

Security is Job 1

The question every company must ask is how to protect the mobile device and the data it accesses. “If you expose systems to the outside world, you have to deal with security,” says Interstates’ Steenhoek. “What if a technician loses a cell phone? Is the risk worthwhile?” A multi-pronged approach is desirable. ProSoft i-View makes cumulative use of security features such as passwords, encryption and VPN tunneling to secure its process data.

[pullquote]Planning for security upfront is essential. “Mobile access applications are subject to security levels in the IT infrastructure,” says Ken Brunnbauer, Rockwell Automation commercial programs manager for the services and support business. “Without the right planning, they might not work as designed because of established security configurations.”

SKF recommends bringing the IT person into the sales discussion. “The larger issue is what the local IT group will do to let you to get through the firewall and connect into the intranet,” says Brady. “Whether it’s VPN or a secured tunnel from the phone company, you have to stop and address it.”

Best-in-class companies are three times more likely to have the ability to secure their mobile devices, according to the Aberdeen Group study. “The biggest balancing act is securing the devices without putting up roadblocks for users,” explains Prouty. “For instance, requirements to enter a password at each startup, every time the device is re-powered from sleep mode, and every time you access email can become an end-user nightmare.”

Looking forward

Soft dB intends to increase its investment in mobility. “We’ll be using more mobile devices because this replaces older, existing technology that was heavier and more cumbersome, had an inferior user interface, and relied on components that are no longer supported,” says L'Espérance.

Vendors such as Endress+Hauser and Interstates are weighing the benefits of wireless apps. “Our next task is to figure out which apps we could provide that would be beneficial to an end user,” says Endress’ Farrow. “What is it they want or expect to be able to do with this sort of technology, and how does it fit into our business and what we offer?”

Interstates is considering the cost of development versus the payback, says Steenhoek. “Is it a trend or a fad that will be obsolete in 18 months?” he asks. “Are just one or two progressive customers asking for it? There needs to be trust in the technology and its reliability.”

Others, like Rockwell Automation, are actively exploring new possibilities. One idea is to have customers install TiVo-like devices to capture and stream data, allowing them to review what happened within a period of time before and after a fault. Rockwell Automation could potentially log into its camera to help determine the cause.

Opto 22’s vision of mobility is expansive. “Moving forward, it won't be limited simply to viewing data,” says Crump. “You can expect nearly all of the functionality automation engineers currently have with a PC to be brought to a variety of different mobile platforms.”

“As people continue to become more comfortable with the technology, acquire smarter devices and build wireless infrastructures into facilities, tablet and smartphone apps will become more commonplace,” says Interstates’ Steenhoek.

Email Contributing Editor Sheila Kennedy, managing director of Additive Communications, at [email protected].