Capital investments are scarce, employment is down and manufacturing is barely ticking over in much of the world, but purveyors of mobile computing hardware, software and wireless infrastructure are still seeing steady — in some cases, aggressive — growth. Word is out about increases in productivity, effective knowledge management and positive culture change in companies that hand out handhelds. Now the barriers to implementation are under siege.

“Life is more competitive,” says Joe Granda, executive vice president, marketing, Syclo (www.syclo.com), which is expanding its mobile software and systems integration workforce. “Organizations have gone to a lot of effort to streamline activities — six sigma, asset management, supply chain — and they’ve done a pretty good job of improving productivity and processes. So what’s the next step? Mobile.”

Mobile computing lets companies leverage office system improvements in the field. You can reduce cycle times to reduce labor costs, improve customer satisfaction and increase product quality; get information into the hands of people and back into the system; and handle regulatory compliance with documentation for the EPA, FDA and Sarbanes-Oxley.

Better information management is breaking down barriers between production and maintenance. “As companies put in more maintenance management systems because costs are high and equipment is breaking down, they find that they now know what the backlog is, but they’re not catching up,” says David Dollar, product manager for IntelaTrac at Wonderware (www.wonderware.com). Operators can collect condition data to help them operate within the design envelope and keep the process or machine tuned. “They can extend the time between maintenance and notify maintenance earlier if a problem starts to occur, so you replace a bearing instead of a shaft and bearing,” Dollar says. Along with extending intervals based on more proactive operation, you can empower operators with correct procedures and focused advice, and lead them through minor troubleshooting.

Mobile devices also are being used to capture uninstrumented process data. Some 40% of equipment isn’t instrumented or has only local gauges. Operators often open or close valves manually, setting positions with verbal communications, and the records are poor. Mobile devices can bring those values into the process historian, allowing the operator to feed information into multiple systems of record.

For example, EPA requires inspections of flanges and valves for fugitive emissions. “You attach RFID tags — not bar codes that can be copied — at the locations,” Dollar says. “You have to be within two inches to scan them, then answer questions to confirm the inspection. Reports are e-mailed to the EPA. The EPA visits less often because the inspections are rigorous and documented, and the EPA accepts them.”

The same wireless infrastructure can be shared among mobile computing, security, building management and control systems. It can reduce capital expenditures and improve reliability when adding measurements for monitoring and controlling equipment, energy and emissions.

“The business case for mobile workers is compelling,” says Paul Brooks, business development, networks, Rockwell Automation (www.ra.rockwell.com). But as shown in Table 1, research shows that manufacturers also see some challenges.

| Key Benefits* | Key Challenges* |

| 1. Empower employees to be more productive | 1. Security concerns/risks |

| 2. Reduce labor costs | 2. Cost of hardware, total cost of ownership |

| 3. Work order accuracy, asset tracking accuracy | 3. Cost of software, integration, service and support |

| 4. Improved compliance documentation | 4. Integrating mobile applications with infrastructure |

| 5. Impact on revenue generation | 5. Hardware quality |

* Manufacturers’ responses to “What are your organization’s key benefits and challenges with regard to the deployment of mobile and wireless technologies?” (Motorola) |

|

Engineer your Ethernet

Most industrial facilities are settling on wireless Ethernet (Wi-Fi) as the primary plant-floor mobility backbone, with radio, cellular, GPS, Bluetooth, etc. used where needed, as needed. Infrastructure costs are coming down as architectures are standardized, application engineers and installers become more familiar with industrial requirements, and competition heats up among industrial and commercial suppliers.

“Ethernet — 802.11 — is being accepted as the network,” says Marty Jansons, networking consultant, industry communications group, Siemens Industry (www.usa.siemens.com/industry). “People are giving wireless a go, trying it in an area that’s unreachable by wires or using it to upgrade a fieldbus system. We see 802.11a, b, g and n.”

In a plant, wireless applications as diverse as security video and real-time crane control can be integrated on one wireless infrastructure by supporting different radios that don’t interfere. “802.11g on 2.4 GHz offers 3 channels, 802.11n offers 3 on 2.4 GHz and 22 on 5 GHz,” Brooks says. “Sharing time is fine for PCs and emission controls, but not for controlling a heater or a crane.”

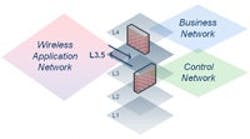

Figure 1. For safety and security reasons, the mobile computing, control and business networks should be separated and firewalled. (Apprion)

For safety and security reasons, the mobile computing, control and business networks should be separated and firewalled (Figure 1), asserts Steve Lambright, vice president, marketing and customer services, Apprion (www.apprion.com).

“Now your wireless infrastructure can support many applications — maintenance, process control, business systems, condition monitoring, security video, emergency notification, voice — so you can share up-front costs,” Lambright says. “You don’t have to justify it on just one application.”

That justification begins by defining what you want the network to do. “Wireless is a shared medium,” says Jansons. “You can have eight people fighting for access, or you can separate them into channels to guarantee access. On 802.11g, you can segregate traffic and have separate names, encryption and passwords. What do you want, what do you need, what are your security requirements?”

{pb}Then, find out what it will take to install it in your facility, starting with a site survey. “WLAN and mesh network planning software can do predictive analysis of coverage in a given facility,” says June Ruby, director, manufacturing solutions group, Motorola (www.motorola.com). “It’s a cost-effective way to plan.”

Software can tell you if the IT network will interfere with plant data transfer, overlap will compromise the security of office wireless or structures will interfere. “Metal shelving and concrete walls can be put into software and simulated using algorithms,” says Jansons. “The survey lets you know what coverage you can expect, decide wired versus wireless and weigh cost versus coverage.”

Wireless can be expensive if a lot of hard wiring is necessary to connect wireless access points. “Repeaters have made that cheaper, but areas with lots of metal are still a problem,” says Dollar. “You can afford 90% coverage much more reasonably than 100%, so consider applications that are designed to run in an occasionally disconnected environment. Mesh networks are coming that may be better.”

[pullquote]When calculating ROI, consider how long the system will run. “Five years? 10 years?” asks Jansons. “Some people use commercial equipment that runs either a, b or g. You may want ruggedized, industrial components that run all three or any one or two. Then you can put the control system on 801.11a and communicate on 802.11g. You’ll need separate antennas, and you get separated traffic with no interference or data overload.”

Every site is unique, or as Jansons put it, “The medium is standard, but there’s always an ‘X’ factor.”

In most facilities, plant engineering initiates the wireless infrastructure project . “They want to try to do a project wirelessly but don’t know how,” Jansons says. “It’s a challenge for IT to understand the requirements of the plant world, but once they do, they can handle it. Start with what you want to do. Learn the technology, and get a site survey from the plant perspective. Then involve IT.”

When it’s time for installation, some plants do it themselves. Some hire system integrators, and some use their IT department. “We do application engineering and can help with or coach the installation,” Jansons says.

Expect a learning curve. Over the course of an extensive implementation at Huntsman Chemical’s Port Neches, Texas, plant, the electrical contractors learned better ways to set up, install and commission. “Number 100 went in in a third of the time of number 1,” says Lambright. “Every facility has its own way of doing things. We’ve learned to combine our best practices and theirs. Over time, we’ve been able to establish proven best practices to design, install, tune, go live and operate complex networks.”

Innovations drive ROI

Advances in software and devices are speeding ROI by making it faster and easier to develop and implement applications. Mobile has become more reliable, versatile and able to handle mission-critical applications. “To ease implementation, use a software platform as a foundation and run pre-built, pre-integrated applications,” says Granda. “Once you have a platform, each application takes less time, training and IT to implement.”

Industry is comfortable with Windows Mobile as an operating system, according to Dollar. “Through Windows Mobile 5, then 6.1 and now 6.5, the platform has really improved over the years, with a lot more capabilities for a richer interface.” It’s certified on many devices, all of which can run the same code. “It handles full VGA, ¼ VGA, Motorola, Honeywell,” he says, “and the same software runs on Windows XP and Vista, so we have to do less development – just what we need to support barcode readers and condition-monitoring devices.”

{pb}Device manufacturers offer handhelds at every price point, set of capabilities, ruggedness and certification, “the right device for every purpose,” says Ruby, “including voice over wireless LAN and interfaces for PBX and mission-critical private radio.”

Here are seven areas users might examine to streamline implementation, according to Joe Granda, executive vice president, marketing, Syclo (www.syclo.com):

- Business continuity: capabilities such as server clustering with failover so people can keep working, and load balancing to keep up with adding users.

- Mobile device management: Know where the devices are and perform upgrades, patches and troubleshooting from a central location. Handle increasing numbers of diverse devices.

- Online, offline: Follow business rules and perform validation without compromise whether on a LAN, WiFi, WiMax, cellular or no network. Manage costs by prioritizing data transmissions by network.

- Lean and clean architecture: No intermediate database, no heavy server-side processing — they don’t scale up and can cause latency issues. Both 32- and 64-bit compatibility for speed. Load balancing and support for virtual as well as dedicated hardware servers.

- Devices and peripherals: Support multiple devices (laptops, Windows handhelds, iPhones, Blackberries) with the same software logic, without rewriting code. “You’re going to have them all thrown at you, along with peripherals such as barcode, RFID, meters and GPS.”

- Productivity and QA tools: Wizard-driven environments ease code development and test.

- Security: Support services (LDAP [lightweight directory access protocol], active directory, single sign-in for multiple applications (CMMS, financial, HR), remote wiping of devices that are lost or stolen. “Everything should be encrypted whether it’s over the air or not.”

The mobile worker can have a walkie-talkie, push-to-talk phone and palm-top computer with docking, all in the same device. “Now, technicians are familiar with the devices and just want to access the applications,” says Cliff Whitehead, business development manager, strategic applications, Rockwell Automation. “They just expect it to happen.”

A security guard might only need a rugged, two-way radio, or he might also need to access video surveillance feeds with a rugged, hand-held, mobile computer. A maintenance technician needs to eliminate paper and capture data, and might use Bluetooth to collect data from accelerometers or temperature probes. Views of the process control system allow them to see and acknowledge alarms, and variables such as tank levels and flow rates.

Devices can use the most appropriate available network for the application. GPS allows triangulation and real-time location you can use to marshal personnel in an emergency. With the right management software, you can get notification if a device doesn’t move or is inactive for too long.

Handhelds range from slightly rugged smart phones optimized for bar-code scanning to Class I, Div. 1 devices you can drop on concrete. “Devices have become so critical to businesses, they don’t want to be without them,” Ruby adds. “Some service plans even offer rapid swap-out for damaged devices.”

Bear in mind that whatever you choose is likely to be only a starting point, with additional ROI coming from applications you’ll discover later. “First, acquire or develop applications that make maintenance more productive. That makes the infrastructure more attractive," says Whitehead. “Once it’s in place, there’s no limit. The ability to make it mobile depends less on the devices than on the creativity and abilities of users, and we never know what people will come up with. The market pulls us into new and creative applications. Your cost may vary.”

The same software tools that streamline commercial mobile phone and IT support are making life a lot easier for administrators of industrial handheld devices, and lead to the same kind of choices for how to source a system (Table 2). The Gartner Group (www.gartner.com) associates the lowest per-unit, three-year costs with a strong customization of a mobile enterprise application platform (MEAP), estimates somewhat higher costs for hosting a packaged system on-site and sees scratch-built systems as a wild card. Gartner finds the low up-front costs of software as a service (SaaS) to be more than offset by monthly fees before the three years are up.

| Model | TCO* |

| Mobile enterprise application platform (MEAP) $50,000 customization Built-in mobile device management Minor upgrade path |

$992 |

| Packaged, on-premises $20,000 server license Ongoing upgrades |

$1,080 |

| Build from scratch $200,000 customization Major upgrade at three to four years |

Varies |

| Software as a service (SaaS) $20,000 customization Ongoing upgrades |

$2,340 |

*Three-year total cost of ownership per seat for 500-seat mobile field service management system (Gartner Group) |

|

Seven areas of concern and how your implementation model affects them are described in the sidebar, “Pondering Platforms.”

Regardless of how it’s implemented, remote administration is unequivocally a boon to commanders of fleets of devices, allowing software changes and hardware enable/disable over the network. “With our mobility services platform (MSP), you can drill down into devices and do revisions, operating system patches, even disable or wipe from a central location,” says Ruby. “You don’t have to physically bring in devices.”

Users may have thousands of mobiles deployed around the world. “With Microsoft Systems Center Mobile Device Manager, we can turn capabilities on and off,” says Dollar. “For instance, if security requires it, we can turn off the camera on hundreds of handhelds without touching them. A lost handheld can be remotely wiped so it can’t log in.”

Get it done

With so many tools available on mobile devices — the CMMS, operator screens, accessing machine operating conditions, work orders, instructions, one trip for parts and tools, “the case for a wireless infrastructure is becoming a no-brainer,” Whitehead says.

But because so many departments have a stake in the outcome and a use for a mobile computing and wireless networking infrastructure, a critical factor for success is communication among groups — maintenance, engineering, security, safety — to agree on needs and priorities.

Brooks sees the necessary disciplines converging in four areas:

- In network technology, one software tool makes a common platform.

- In the physical network, one infrastructure separated logically for different applications.

- Culturally, maintenance and IT are recognizing their interdependence and more often share responsibilities, goals and a common language.

- Organizationally, maintenance and IT remain different people, but more often have the same boss: a production director who wants to take responsibility for things critical to production, including IT.

“Any battle between maintenance and IT is a waste of time,” Brooks says. “The leaders will be the ones most adaptable to the other’s needs.”

When mobile computing is working well, it helps everybody. “The fact that a work order can be completed on location — quickly, accurately and in real time — drives accountability down to the operator,” says Lambright. “But it also drives it back up to management. Now the operator can make management aware of the situation here and now, and it’s incumbent on them to take advantage of it.

“At Huntsman Chemical, this concept changed the perspective of operators and technicians. It lets them hold management accountable for what they think is important to the plant.”