Genentech’s focus on implementing a performance-based monitoring strategy led the company to a non-invasive wireless monitoring solution. By implementing the solution on steam traps and critical research equipment, Genentech was able to improve its asset management strategy, find energy savings and improve uptime.

Genentech’s mission is to meet unmet medical needs. One of the goals in the Corporate Facilities Services group is to operate a world-class facility. The key focus area to achieve this goal is continuous improvement of facilities and maintenance systems to reduce operating costs. By driving down operating costs, more funds can be allocated to developing the product pipeline and achieving the mission.

The guiding principles for identifying and executing continuous improvement projects include:

- Improving plant asset management by implementing a performance-based maintenance strategy. Genentech has a well-established, time-based asset maintenance program. Transitioning to a performance-based strategy will also allow Genentech to predict equipment failure and understand an asset’s life cycle.

- Reducing energy costs. Identifying methods to improve the efficiency of energy consumption will reduce energy costs and improve the bottom line.

- Improving uptime. Research and operations expect the facility and equipment to be functional and reliable. Any downtime in the facility directly impacts the bottom line. Corporate Facilities Services focuses on improving uptime and equipment reliability to help achieve the mission.

Genentech identified several assets that could benefit from a performance-based maintenance strategy to reduce energy costs or to improve uptime.

- Steam Traps. Genentech has an annual steam trap maintenance program. However, throughout the year, steam traps often fail. Steam loss from failed traps was estimated to cost the company hundreds of thousands of dollars annually. Steam trap failures could be prevented or found as they occur using a steam trap monitoring system, resulting in significant energy savings.

- Critical Research Equipment. Ultra-low freezers are critical to research activities. Reliability issues with older stand-alone freezers result in downtime and potential loss of work product. Maintenance activities are performed more frequently to avoid these issues. Performance-based monitoring of these research freezers would allow the maintenance staff to proactively detect issues and prevent failures. This would result in increased freezer uptime and could potentially extend the useful life of the freezers.

The challenges with implementing performance-based maintenance on existing systems include cost and invasiveness. In order to monitor the condition of assets, analog instruments must be replaced or new instruments must be installed to collect data. Traditionally, this work is invasive and requires a process interruption and engineering oversight. Furthermore, the new system must be commissioned for restart. This often includes inspections and leak checks, as well as revalidation in order to return the system to service. These activities often result in an unfavorable cost/benefit ratio.

As a cost effective alternative, Genentech identified a non-invasive monitoring solution, provided by Cypress Envirosystems. Devices are clamped onto existing instrumentation to collect and wirelessly transmit data to a server for trending and alarming. This method eliminates the need for process interruption for installation and minimizes engineering oversight. Table 1 below shows the comparison of monitoring solutions.

| Table 1. Traditional monitoring versus non-invasive wireless monitoring solution | ||

| Traditional monitoring | Non-invasive wireless monitoring | |

| Plant disruption | • Invasive • Process interruption required • Wiring required |

• Non-invasive, clamp-on devices |

| Reliability | • Power source required • Real-time data collection |

• Battery operated • Pre-programmed data collection rate |

| Engineering | • Changes existing system • May require engineering change management • System re-commissioning required for restart |

• No changes to existing system • Minimal engineering change management • No system restart required |

| Infrastructure | May require new software | Interface available for integration into existing infrastructure |

| Cost | $3,000 - $5,000 per point | $750 - $1,500 per point |

Genentech was concerned about the viability of a new wireless technology in the facility. Although the traditional monitoring solution was more challenging to implement, it was a technology that was commonly used on campus. With the non-invasive wireless solution, there were concerns with data integrity, wireless security, and data integration into the existing infrastructure. To demonstrate proof of concept, as well as to quantify potential savings, Genentech partnered with Cypress Envirosystems to pilot this technology on specific equipment.

Results

Steam Traps

Wireless Steam Trap Monitors (WSTMs) were installed on 56 steam traps at a cost of $42,000. The WSTMs were intended to provide early indication of steam leakage or blockage, which lead to failure. Data was collected on a “blue box” server for trending analysis.

Fourteen steam traps showed signs of failure. The maintenance team investigated and the traps were replaced. Early detection saved an estimated $53,000 in annual steam loss. The project payback was 10 months.

Critical Research Equipment

Wireless Freezer Monitors (WFMs) were installed on 20 critical freezers at a cost of $20,000. The WFMs measured parameters including low-stage and high-stage compressor amperage, internal chamber temperature, and door open/close status. The data collected was intended to provide early indication of refrigerant leaks or door seal issues, which lead to freezer failures.

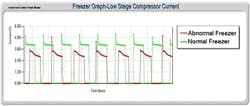

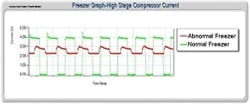

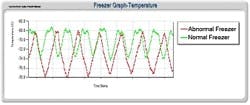

Four freezers showed signs of distress. Sample data trends are shown in Figures 1-3. Even though the temperature profiles of the freezers showed no problems with freezer functionality, the compressor amperage profiles indicated that freezer failure was imminent. The issues were investigated and resolved by the maintenance team without having to replace the freezers. Early detection saved an estimated $20,000 in replacement costs. Furthermore, Corporate Facilities Services repaired the freezers before they failed and minimized the risk of losing any research samples, thus protecting the product pipeline. The project payback was immediate.

Figure 1. This graph shows low stage compressor amperage over time for two freezers. The profile of the abnormal freezer indicates a potential refrigerant leak.

Figure 2. This graph shows high stage compressor amperage over time for two freezers. The profile of the abnormal freezer indicates an electrical problem with the compressor.

Figure 3. This graph shows temperature over time for two freezers. The profile of the abnormal freezer indicates a potential door seal problem.

The pilot projects demonstrated that the non-invasive wireless monitoring solution was a successful tool in implementing a performance-based maintenance strategy. Installation of the non-invasive wireless monitoring solution did not disrupt plant operations. There were no issues found with wireless security. The data collected was easily integrated into Genentech’s existing infrastructure. The overall results showed a payback period of less than one year.