The current generation of experienced plant professionals is being lost to retirement, displaced by job relocations and antiquated by advances in manufacturing technology. The supply of appropriately skilled, educated and trained personnel is, at best, strained, and in many places, totally inadequate.

An April 2008 survey of 100 senior manufacturing executives indicates that in the past three years, the need to replace lost skilled workers has grown from a concern to a crisis. The executives say the shortfall will cost their companies an average of $52 million, and even more, $100 million, for the nation's largest companies that report more than $1 billion in annual revenue. The benchmark survey, commissioned by Advanced Technology Services Inc. (ATS) and conducted by Nielsen Research, says that during the next five years, about 40% of your skilled labor force will retire.

Improve productivityThe white paper, “Workforce Trends: Tools for taking control of today's skilled labor shortage,” by Advanced Technology Resources (ATS) provides guidance on what companies can do to stem the tide. It shows the immediate and long-term benefits of taking proactive steps to recruit, train and promote a multiskilled labor force to make factories more productive in-house, so manufacturers won't look elsewhere for less-expensive production alternatives. Find it at www.advancedtech.com/workforce. |

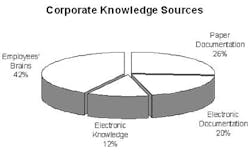

We can be confident that societal, government and market forces eventually will close the gap, but in the meantime, how much institutional knowledge can you afford to let walk out the door? Most would agree that a company’s competitive edge relies heavily on its intellectual capital — the knowledge it possesses within its organization — and much of that resides in its employees (Figure 1). It makes sense to take steps now to capture the departing expert’s critical know-how.

The same strategies and infrastructure you use for capturing knowledge also can provide a way to gather and compare alternative approaches, distill best practices and distribute them to dispersed personnel, shifts and locations. Captured knowledge also might significantly reduce the time and expense of disaster recovery, and can be invaluable for training new recruits.

Rely on the Web

It seems that everything anyone really needs to know can be found on the Web. But as mathematician and writer John Allen Paulos said, “The Internet is the world’s largest library. It’s just that all the books are on the floor,” to which a wag once added, “and the lights are off.” It takes some time and skill to home in on truly relevant information, and experience is helpful for determining which sources can be trusted.

Figure 1. Employees’ brains remain by far the largest repository of the knowledge companies rely on for a competitive edge. (Source: The Delphi Group)

But the public portions of the Web can’t offer details about your own facility, nor a secure structure for storing that site-specific (and perhaps proprietary) information. And other people’s Web sites aren’t very useful for capturing know-how or organizing, storing and sharing your body of knowledge.

Subscribe to wisdom

Much of the Web’s most arcane but useful knowledge resides behind paid subscriptions or pay-by-the-download. Paid access to a reputable source might ensure that information is accurate, complete, organized and up to date. And a paying client might obtain a competitive edge by getting information that’s not available for free.

One example is SKF’s @ptitudeXchange. Originally planned as the database model for the company’s decision-support system, it gives access to knowledge and experience in rotating equipment, machinery, components, software and instrumentation from SKF and its alliance partners.

Contents focus on asset management (achieving the lowest total cost of ownership with maximum availability, performance efficiency and product quality), reliability engineering (RCA, FMEA, predictive maintenance, vibration analysis, inspection techniques and thermography) and mechanical maintenance (alignment, balancing, bearing installation and equipment history tracking).

It includes overview documents, technical handbooks, white papers, application notes, best practices, interactive tutorials and benchmarking information, as well as interactive advisory systems for help with day-to-day analysis and decision-making. There also are public and private forums, where you can get answers to questions or search for and find solved problems.

“If someone finds a problem with a motor or imbalance in a fan, they can look for an easy answer in the repository and prevent a recurrence,” says Rob Bretz, team leader, SKF Internet, SKF (www.aptitudexchange.com). “We built the capability to add interactive tutorials on subjects like bearings, lubrication and thermography that we could turn into courses with certificates of completion. Then we added expert systems, like LubeSelect, so you could enter parameters and get information on what lubricant to use and the proper service regimen.”

Part of the knowledgebase can be accessed for free after registration, whereas other parts require a subscription. “From the beginning, @ptitudeXchange has been intended as a profit center, where we sell content,” Bretz says. “The bulk is behind subscription, and some of it is proprietary and accessible only to specific organizations. We also include it as part of service packages and employee training programs.” For example, the product support package for a vibration system could include @ptitudeXchange.

Add smarts to internal systems

“When a seasoned individual is getting ready to retire or take their leave, take them off their job for the last two to six months and grill them on different aspects of the jobs they’ve done for 30+ years,” suggests Al Yonkman, a recently retired DTE control and computer systems engineer now working with IBM (www.ibm.com) as a business development executive. “Capture that information in standard work instructions [SWIs] linked to job plans so people can access them without trying to dig up Old Joe’s last comments to find out what you do in a particular situation.”

Knowledge that’s used routinely to perform regular tasks can be added to a computerized maintenance management system (CMMS), document-management system and engineering software. Associate it with specific tasks so it’s readily accessible whenever the task comes up.

Engineering programs can be interlocked to reflect institutionalized knowledge. “If you’re designing a multiple-pole line extension, the pole tops and pole spacings are pretty standard,” Yonkman says. “You can build them in so a fairly new employee is able to design a sophisticated line because the system won’t allow you to, for example, put a 4,800 V insulator on a 13,200 V line, or plan a 350-ft. span when the guys will only support a 200-ft. span.”

The approach depends more on following procedures than on buying specific software. Many CMMS packages allow job plans to be linked to work orders so crews have access to drawings and standard work instructions. A variety of document-management systems allow you to store, sort and assign versions to the documents, and more than one design package can accommodate a rulebase.

“The key is, when you’re doing work, you don’t want to have to do a bunch of sorting and searches,” Yonkman says. “You tend to work with specific construction units and job plans, and when you work on a piece of equipment you click on it. What comes up is a job plan that reaches out and grabs sketches and SWIs associated with that piece of equipment so you’re not searching and sorting.”

Once you’ve built and populated the database, you can improve, build on and modify standard work instructions based on learnings. “The idea is, it’s never done,” Yonkman adds. “You’re always learning — new equipment, new design processes, new maintenance approaches. On a day-to-day basis, as you get new equipment and new procedures, you continue to build that SWI database so it’s available for future generations.”

Build a better database

Advanced Technology Services (ATS, www.advancedtech.com) began building its information system — called Knowledgebase. When the maintenance services company gets involved in a new site, teams go through the files, scanning in manuals and documentation. “We use a Web-type database and Google search technology,” says Jeff Morrow, ATS KnowledgeBase database administrator. It can search by word or phrase, and the full-text searches can be filtered to a particular site, keywords, equipment type, etc.

Along with scanned documents, the system captures information from maintenance work orders, technician’s questions and answers from its “Factory Forum,” and relevant information from the public domain. “We now have about 14,000 files and expect 100% growth during the next year,” Morrow says. “About 20% is tribal knowledge — PMs, procedures and real-world tips and tricks.”

That tribal knowledge isn’t easy to capture. “When root-cause analysis [RCA] is mandatory — and we have rules for that, based on safety, regulations, equipment criticality and excessive downtime –— the analysis goes into the system,” Morrow says. “We’re using RCA-based problem/solution forms that are filled out by the technician and signed off by the maintenance planner and site management. This is how we get the knowledge that’s not in the manuals.”

Users can rate information for how much it helped, or comment on accuracy or missing information. Higher ratings raise the information’s position in the search results.

“We just used the knowledgebase this weekend to pull up the manual for a measuring instrument on a bearing production line,” says ATS Traveling Technician Jason Scales, who was caught in transit between jobs near Hamilton, Ala. “Until we found the manual, we thought we would have to shut down the line and send the instrument back to Japan.”

Scales says he routinely uses the system to prepare for a site visit. “With a machine model and number, we can access manuals, schematics and PLC logic,” he says. “It’s a lot better than flipping through hundreds of pages of manuals.”

It also comes in handy for troubleshooting. “We had a drive on a Gleason machine tripping,” Scales adds. “The knowledgebase gave us a tip to adjust the gain, which solved the problem. It saved us a lot of time and trouble.”

ATS now provides services at about 60 sites, so an important function is to share, as well as capture, knowledge. It also helps for training new employees. “It drives us toward best practices because we can capture and share the best way to deal with a particular machine or problem. And as we add more, it does more,” says Vlad Bacalu, product manager, ATS.

“It’s a great tool that improves efficiencies,” Morrow adds. “Every day that you don’t use it, you risk losing knowledge.”

Another option is to buy a software system preloaded with information relevant to the equipment in your facility. Some such systems allow you to modify the information and add specific details to build a powerful, comprehensive support and reference system.

For example, SKF’s @ptitude Decision Support system offers failure mode and effect analysis (FMEA) and failure symptom information for more than 100 kinds of equipment, from shafts and bearings to heat exchangers and motors. It also supports and monitors operator-driven reliability (ODR) inspection data and can accept process data via OPC. Decisions are made on multiple variables.

Like a seasoned reliability expert, Decision Support can help identify problems, determine how serious they are, recommend a course of action and priority, and highlight potential risks to productivity, quality, worker safety and the environment.

“The system is preloaded with the models needed to support a user’s technology,” says Scott Brady, director of marketing and ODR, SKF. “We might have to add some special aspects for a specific piece of equipment, but that part is small compared to the standard information.” The plant can use the same editing tool to make changes to variables such as rules and detection levels, or to add information from other sources such as engineering and purchasing.

In practice, as an expert nears retirement, “We set up the system with content, get Old Joe and go through it with him,” Brady says. “Perhaps the settings for temperatures or vibration will have to be changed. Old Joe might say the pipe starts shaking and you’ll pick it up. When the process interacts, we’ll use OPC and pick up the process conditions to set the rules.” After Old Joe is gone, if the system says there’s a fault, a new technician can see why Old Joe said it’s a problem. “It’s not a black box,” Brady says.

Plants are trying to monitor more equipment with fewer people, and many find that there are too many data to look at. “You can use it as a highly technical filter,” Brady adds. “It looks at all the data and tells you which parts to look at.”

At a plant in Brazil, “One of our contracts has 5,000 pieces of equipment and two analysts on contract,” says Luis Econom, SKF product line manager, software. “They can do the job because they’re presented with the information they need on the critical assets.”

Get more from controls

Your automation and controls might be holding a lot of information about your facility. Some plants are leveraging the expertise and historical data embedded in advanced process control (APC) and change-management systems to empower operators, pinpoint process problems and expedite repairs.

“The new generation of workers expects information on demand, from their experience with Google and the Web, rather than by studying or by reading manuals,” says Don Hart, vice president, Rockwell Automation Pavilion marketing (www.pavtech.com).

APC can handle disturbances and non-steady-state conditions such as startups and shutdowns where operators traditionally ran under manual control using their experience. This can be helpful in complex processes. “We have a polymer plant in Canada with 1,300 variables,” Hart says. “It’s way beyond operator capabilities.”

Pavilion Technologies is widely known for APC and emission compliance/virtual analyzer packages. In 2007, Pavilion expanded into production and performance-management software to improve visibility of APC performance with information such as time on control, time at constraints and valve performance metrics. This system has been extended to display metrics and analytics of entire plants.

Meanwhile, change-management systems guard against trouble on a much simpler scale by unobtrusively backing up variables into larger programs. During normal operations, any changes, tweaks and modifications are being captured for change management, disaster recovery and calibration information.

“Technicians can store standard operating procedures, predefined actions or variables in an integrated system, at the hands of operators or maintenance engineers, not in a file cabinet,” says Scott Miller, business manager, asset management, Rockwell Automation (www.rockwellautomation.com/rockwellsoftware/assetmgmt).

It can be a challenge to justify the ROI without having a disaster and losing all your machine settings. “It’s an insurance kind of sale,” Miller says, “but its value is in the daily occurrences that add up. Changes in run rates due to small changes don’t shut the plant down, but they add up. The system lets you detect and back out small problems.”

“One client had a problem they worked on over a weekend. They thought it was in the automation system and made about 150 modifications — tweaks — before they figured out it was actually a mechanical problem. They fixed that in an hour, but now the machine was out of control. They were able to point back 150 versions and put the machine controls back where they were on Friday.”

Sublet expertise

“Years ago, there used to be big maintenance programs,” says Tim Last, business development manager, Atlas Copco (www.atlascopco.com). “We used to train customers and sell spare parts, and show owners how to maintain and troubleshoot. But now departments aren’t doing — they’re managing and outsourcing.”

Industrial facilities have always relied on outside services for niche expertise as well as manpower to help handle short-term heavy work loads. Now many are trusting contractors to fill a broader range of knowledge gaps.

Get wikied“I think every company should consider starting its own wiki. We put everything in ours — client information, progress reports, etc. It’s searchable and much more convenient than e-mail threads. We have nine people on our international team, most with English as a second language. E-mail, instant messaging, teleconferences and wikis — I’ve tried them all and the wiki is best for aggregating information and keeping records. Search is so much better than it used to be. Every company should keep track of what they’re doing in a large database.”

|

“It saves cost due to economy of scale,” Last says. “We know compressors, and we improve reliability of pressures and machines. We actually do the preventive maintenance and we change parts in time, so uptime has risen from 80% to 90% 10 years ago to 99.9% these days.”

Focusing on an area of expertise and competing against other service providers can give vendors an edge over your in-house staff. “We are always learning new things and trying new things, and some of them work,” Last says. “We often can solve a problem, reduce a cost, or make an improvement at much lower cost than clients could do on their own.”

Vendors often offer global breadth and deep expertise. “Wherever you are, we have people with 10 years or 15 years of experience,” Last says. “People tend to stay with us, so they know the processes and machines. The same is true of our distributors.”

Service technician pools are growing quickly. “There’s lots of competition for the kinds of people we’re recruiting,” Last adds. “We must offer good possibilities, packages and training.

“Will a service provider watch out for your best interests? We offer value for money, to help you invest in solutions like systems that save energy, monitor compressors 24/7, etc., that we’ve come up with because we’re monitoring so many compressors in so many places. And there’s plenty of competition — companies that can do similar things — and that’s raising the standard.”

E-mail Editor in Chief Paul Studebaker, CMRP, at [email protected].