Hand out handhelds for power over everyday maintenance

Mobile computing is a technology that most plant managers, maintenance supervisors and technicians see as nice – maybe too nice – and unnecessary for their work. You’ve done alright for many years without it, so you must not really need it, and besides, it looks fragile, complicated and expensive.

Don’t try talking that way at San Francisco Water’s West Bay Facilities, where Wonderware tablet PCs have been saving time on PMs for three years now (Figure 1).

Figure 1. Tablet PCs have been saving time on PMs for three years at San Francisco Water’s West Bay Facilities. Along with transmitting maintenance and calibration information, the mobiles are operator interfaces for the control system.

Along with transmitting maintenance and calibration information, the mobiles function as operator interfaces for the control system.

“With two operators on a shift, we used to always have to keep one in the control room,” says Dee Cutino, superintendent. The primary operator is responsible for instrument calibration, while the secondary operator is devoted to routine maintenance. The secondary operator would have to stop working and take over monitoring the control room when the primary operator needed to leave, for example, to calibrate turbidity meters. “Now the primary operator can take a tablet with him so he can start and stop equipment, acknowledge alarms, etc.,” says Cutineo, and the secondary operator can stay on his rounds.

The operators perform 300 to 400 PMs per month, plus plant rounds, quality sampling, and more. “In the past, we had trouble getting all the PMs done,” Cutino says. “The mobile system saves us two hours to three hours per day, which has allowed us to be more efficient and get more work done -- more preventive maintenance gets done without interruption.” The tablets also let them write CMMS work orders in the field, “which is helping us capture better records,” he adds, “and our CMMS is tied into Purchasing, which helps expedite repair parts.”

Much like the car phones of the 1980s that let salespeople make a call without stopping at a pay phone, mobiles have excelled for years at streamlining existing tasks, such as making rounds, entering data into a CMMS and tracking work orders.

Now, with novel features like full PC capabilities, Web access and multimedia communication, mobiles are beginning to offer new ways to get a job done.

When you see what the systems are doing, understand how they work and start to imagine the possibilities, you may decide your operations are worthy. After all, if Cutino, the UPS deliveryman and the cable guy get to play, why not you and your maintenance team?

Power in your palms

West Bay Facilities’ application runs on a Microsoft tablet PC with Windows Mobile and Wonderware InTouch. The tablet has WiFi, Bluetooth and PCMCIA slots for other devices, such as cellular communications or proprietary capabilities, and specialized covers to provide protected access to antenna signals.

“It uses Ethernet to connect to a main network, then to a PC and the control system,” says David Gardner, product manager, Wonderware (www.wonderware.com). Access through a VPN provides secrity.

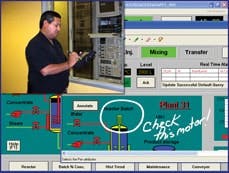

The company’s InTouch software leverages tablet PC features such as inking (users can write values into data links in their own handwriting) and annotation (users can mark up a graphical display with pens and highlighters). Operators can mark up displays and e-mail, print or save the screen capture to facilitate troubleshooting and explanations (Figure 2).

Figure 2. Features such as inking and annotation let technicians mark up displays and e-mail, print or save the screen capture to facilitate communications.

“Three years ago, the devices were seen as expensive,” Gardner says. “That was partly due to their ruggedized construction – they’re IP67, rated to three feet underwater and a four-foot drop onto concrete.” As prices come down and paybacks become clear, the cost of the tablets is less of an issue.

“Then there was also the fear of wireless -- that it wouldn’t work in industrial environments, that it lacked security,” Gardner adds. “Better understanding has led to acceptance. The wireless infrastructure wasn’t there, but now it is, at least in the process industries. In some cases it needs to be extended, but it’s there.”

When peripherals converge

Capabilities emerging in commercial applications for wireless phones and laptops are quickly and cost-effectively being adapted for industrial mobiles. Part of the challenge is making the best use of limited display space on an industrial handheld (Figure 3).

Figure 3. Part of the challenge for sophisticated applications is making the best use of the limited display space on an industrial handheld.

“The small screens are like looking at your application through a keyhole,” says Marty Osborn, senior director of industry product management, Infor EAM. “They’re becoming more configurable so you’re able to display what you need.”

Those compact displays are being used to communicate using images and schematics rather than just text. “A visual representation is worth 1,000 words,” says Bill Padula, vice president, solutions architecture at Syclo (www.syclo.com). Visual representation leads to positive identification and common terminology, “a widget versus a thingamajig,” Padula says, “or where you need a visual reference to be consistent, such as degree of pipe buildup or corrosion, or an unambiguous representation of a switch position or a needle on a dial.”

You can add voice recognition capabilities for “heads up and hands-free” operation using text-to-speech and speech-to-text conversions. “It makes data entry better, safer and more productive,” Padula says. “Voice recognition isn’t yet perfect on mobile or even on desktops, but simple, one-word or short phrases do work. It will get better as computing power and memory increase, but it’s usable now and adds value.”

Digital cameras can be connected or built in to let users capture and store images of equipment, damage, as-found/as-left, etc. Signature-capturing devices and mobile printers provide accountability and paper trails, or produce bar-coded identification labels for inventory or asset tagging. And sensors such as voltmeters or accelerometers offer direct input of condition-monitoring or troubleshooting parameters, reducing data-entry errors and the number of devices a technician must carry.

The RFID connection

RFID has been the center of a lot of hoopla during the past couple of years, inspiring intense consideration of its potential for facilitating industrial maintenance. “It’s good in the right application, but you have to know what you’re trying to do,” says Padula. “Do you want simply to replace bar codes? Keep track of inventory? Store information?”

In a typical mobile application, calibration or condition information is gathered during rounds using the keys, a stylus or touchscreen, or by downloading it over wired or wireless connections.

“With RFID, we’re able to pull readings off a machine, like run-time hours and lift hours from a fork truck, or energy consumption,” says Mick Milnark, president, Blue Dot Solutions (www.bluedotsolutions.com). “With an RFID device connected to the motor or meter, you can walk into the area and boom – you’ve got 50 readings loaded into the mobile and the CMMS.”

RFID also is finding value as an asset tracking/locating device. The traditional approach tracks passive RFID tags on assets as they pass through a doorway. But compared to a real-time location service (RTLS), “Passive RFID is a limited technology,” says Hesh Kagan, director, wireless programs, Invensys (www.invensys.com). “It can detect that an object has passed a portal or come over a fence. RTLS tells you where it is.”

RTLS triangulates on the strengths of signals from asset-mounted, battery-powered active RFID transmitters. The signal strengths at various receivers in a WiFi mesh provides an approximate location, which can be made more precise by training the system with “fingerprint” patterns of objects in specific places.

“It’s mainly software on the WiFi network, so it’s very inexpensive to implement,” Kagan says. “AeroScout has been doing it.”

Adding GPS is another way to track asset locations. Once the coordinates are loaded, Padula says, “The locations help you find the assets, select the right one for the work order, schedule and route based on distance and location, and verify the presence of the technician with ‘I was there’ time and date stamping.”

PC power and the Web

When mobiles are packed with enough power to run multiple applications and support Internet browsing, they easily can transcend any preconceptions that they’re simply for streamlining traditional maintenance processes. Technicians can process data, notify coworkers, access documentation, refer to current procedures, consult experts, collaborate on troubleshooting, generate reports, have system problems diagnosed, order parts, share images and send e-mail to their spouses that they’ll be home for dinner, all from the same device.

For example, Infor partnered with Blue Dot Solutions to produce Infor EAM Advanced Mobile, a mobile infrastructure that supports functionality including GIS and GPS, RFID, multi-dimensional barcode reading, and integration with advanced calibration systems. Also, it supports communication with back-end enterprise systems such as ERP and human resources.

The Blue Dot partnership provides a multichannel access gateway (MAG) to support multiple applications. It enables access to mobile operations with Infor EAM, other Infor products or other existing systems in the enterprise. Infor says that according to industry analysts, the MAG approach reduces the cost of ownership for mobile applications by as much as 30% to 50%.

“It allows the system administrator to do powerful things,” says Milnark. “We can see each group and click down to a single user – memory status, battery power, even monitor and remote control the mobile device over wireless. It’s good for training, support and troubleshooting -- instead of shipping it in, we can work with them to solve a problem.”

Another powerful PC application is Tandberg’s FieldView, a high-resolution mobile video system that enables remote workers to collaborate and troubleshoot field issues with centrally-located experts. As examples, onsite technicians can visually share and illustrate line equipment malfunctions visually with remote experts, and oil platform workers can walk through repair procedures with a vendor onshore.

The FieldView device looks like a traditional camera and operates like a traditional video endpoint, but has two-way VoIP and one-way video. The software can control the device remotely, enabling experts to focus and even zoom in to share and discuss detailed video images. Still images can be annotated in real time, and live video can be shared with multiple office locations, enabling full team discussions.

“FieldView’s handheld portability makes it possible to highlight detailed products, processes and machinery that otherwise would be hard to share visually,” says John Paul Williams, global business development manager, manufacturing, for Tandberg (www.tandberg.net). “Companies don’t have to remain at a standstill while they wait for a specialist to come and investigate the problem physically. Operations keep running.”

Today’s all-in-one

Responding to demands by its more advanced vibration analysis technicians, DLI Engineering integrated many of today’s capabilities into its DCX mobile system (Figure 4). The system uses a hardened tablet computer made by DRS, with DLI’s data acquisition card and a triaxial sensor. It runs high-level software – Windows XP and a full desktop version of vibration analysis and diagnostic software, as opposed to approaches where data is acquired and later downloaded into a desktop workstation for analysis.

Figure 4. Windows XP and Web connectivity give users of this tablet-based vibration analysis system real-time access to extensive knowledge and support.

“Customers want all the history and tools on the floor, and appreciate the XP system so they can load other things onto it as well, such as e-mail,” says Dean Lofall, director of products and systems engineering at DLI (www.dliengineering.com).

With wireless, they’re integrated with peers around the company. They can send alarms to others’ attention, and interface with Scheduling to get problems fixed. They have more freedom and power to communicate in real time.

Wireless technology can be integrated with software so results go into the CMMS.

“And if they’re testing and see something or hear a noise, they can check the CMMS history and scheduled work,” says Lofall. “The DCX can access the CMMS while constructing or performing tests, and you can streamline changes to future work orders and update equipment histories in real time.”

Web connectivity gives access to DLI’s knowledge base. “We have resources available through the Web that they otherwise wouldn’t have – references, etc. – so if they see something they don’t understand, they can identify it,” Lofall says. “They also can access our online technical support. With GoToMeeting service, if the DCX is connected to the Web, our tech support guys can get right on their desktops and help them out while the guy watches them.“We knew it would be convenient, but we didn’t realize it would turn out as wonderful as it is. It’s a great opportunity for the field technicians to get the support they need.”

Avert the crisis

Increasing availability of wireless networks in industrial plants; proliferation of PC, wireless and Web capabilities; and falling costs of ever more sophisticated mobile technology are brewing up a “perfect storm” to counteract the growing skilled worker shortage attributed to retiring baby-boomers, high-tech manufacturing systems and aging infrastructures. Mobile’s ability to instruct, guide and empower workers might be just what we need to close the gap, mitigating the shortage of highly-trained and experienced technicians with wireless tools that can show-and-tell operators each step of the best way to perform their task.