For many years, heat exchangers and chillers for power stations have been cleaned by sponge balls repeatedly circulated through their small pipes. Use of sponge balls for pipe cleaning such systems has been known to the industry for quite a while. The German company, Tapproge, has been designing and building heat exchanger and chiller systems for large power stations for more than two generations. Similar companies in the U.S. include WSA and Hitachi. All deal mainly with large-caliber systems typical to power station applications.

Smaller systems, designed for use in office buildings, shopping malls and small industry plants, however, usually have to make do with manual cleaning. This, of course, can be a tedious and time-intensive process, but there are other, more detrimental drawbacks: Manual cleaning is also highly wasteful of water and can involve large amounts of chemicals and softeners, which are both expensive and harmful to the environment.

Until recently, efficient sponge ball systems were not available for smaller industries, and as a whole sponge ball cleaning in systems of all sizes suffered high loss of sponge balls, leading to interruptions and inefficiency in such cleaning operations.

C.Q.M Technologies Ltd., (www.cqm-tech.com) Tel Aviv, has changed the paradigm. Located in Israel, a country that receives very little rain per year (about 400 mm or 16 inches), C.Q.M. has had to become extremely efficient in its water use.

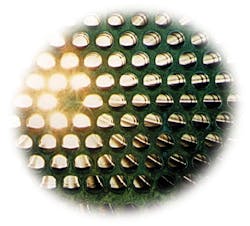

Clean heat exchanger pipes as maintained by ATCS

The company perfected a trap system for the retrieval of sponge balls which results in zero-net-loss of the balls, even when the system is applied to small-caliber applications, in any type of cooling system. This allows the cleaning systems to be installed in numerous system applications, such as HVAC in buildings, small industry and chemical processing plants.

Having penetrated the small commercial and industrial market in Israel and twelve other countries, C.Q.M turned its attention to power stations. Such environmentally sound and efficient automatic cleaning systems are of particular use for large-scale systems such as power stations. The use of the innovative retrieval system trap has proved to be highly advantageous, both to the power station bottom line and to the environment.

Caption: ATCS (Yellow parts) installed in Power Station Heat Exchanger

A well designed, automatic sponge ball system has a tremendous impact on the performance of any cooling system in particular, and on economy in general.

Sponge ball pipe cleaning ideally involves passing the sponges evenly through all conduits, therefore allowing the condenser/heat exchanger to operate at its maximal rated efficiency. This can mean efficiency and electricity/fuel savings of 10 to 30% compared to conventional cleaning methods. Since many facilities chillers can use up to 50% of the total power, this becomes a major consideration. In the U.S. alone, chillers use up to 20% of total power generated. Recovering a sizable part of this energy can have national economic consequences.

In an ideal sponge ball cleaning, absolutely no balls should escape to the environment, and the power station or other user does not have to buy replacements on a frequent basis. In a large power station, this factor alone can yield savings of tens of thousands of dollars yearly. Moreover, the environment is spared the pollution by waste sponges, and the cooling tower is not at risk of clogging by the escaping balls.

We cannot overexpress the merits of our Automatic Tube Cleaning System (ATCS ) sponge ball cleaning method, says C.Q.M general manager Ziki Livni. Livni, an engineer with 30 years experience in cooling systems, describes success with ATCS at diameters of up to 72 inches. Performance tests for such a custom system in Torino, Italy yielded full power at guaranteed heat rate.

Technological savvy and attention to details even in ACTS using balls as small as a one-inch diameter can pay off big, and make a huge difference in the operation of any cooling system, even as large as those needed in power stations.

Levi Wiener is a certified Engineer, a marketing consultant and the Manager of the Marketing Consortium Water and Environment Israel, under the auspices of the Israel Export and International Cooperation Institute.

Sample return on investment computations showing the economics of a sponge balls automatic cleaning system.

In general, the investment in an automatic tube cleaning system installation is recovered in one year or less. (Actual figures vary according to installation type, water quality, temperature, duty cycle, etc.)

There are several types of savings. Consider a sample air conditioning system of 800 TR output capacity. The circulated water capacity is 80 percent water = 640 m/h, and assume that the system works 7,000 hours per year (approximately 80 percent of time).

* ATCS Automatic Tube Cleaning system

** SR Scale Remover

- Quantifiable Savings

a. Energy (Electricity)

With an ATCS and SR installed, system operation with clean tubes in the chiller/heat exchanger is guaranteed. Fouling of these pipes by scale, silt, biomass or other materials impedes heat transfer and reduces the cooling efficiency of the system.

Technical literature usually assumes one millimeter (0.04 an inch) of scale in the tubes will reduce the heat transfer coefficient considerably, by more than 70 percent. In order to receive the same cooling power, one has to use 36 percent more energy.

The savings in energy for an ATCS equipped cooling system relative to a conventional system cleaned periodically (for example, twice yearly) by mechanical scrubbing of the tubes. Assuming a gradual build-up of fouling in tubes between periodical maintenance cleanings, the tubes will be fouled by an average half a millimeter (0.02 an inch) of scale.

Based on tables in literature, relative savings in electrical power is 15.3 percent on a properly maintained system.

Actual savings depend on cost of energy/electricity. Average cost for industry and commerce averages $0.09/KWh.

Assuming 80 percent efficiency coefficient on chiller, the range of the yearly savings on this item would equal (800 TR x 80percent X 1 KW X 7,000 working hours X 0.09$ per KWh X 15.3percent energy savings) = $61,690.

b. Water

For an 800 TR system as defined above, ATCS typically yields savings of 40 percent on water (usually spent draining the cooling system). (NB: more water is spent by the system to make up for losses, evaporation, etc.).

Total make-up water 640 m_/h X 2.0percent =12.8 m_/h, of which:

- Total water typically drained: 640 m_/h X 0.5percent =3.2 m_/h Total water drained yearly: 3.2 m_/h X 7,000 hours =22,400 m_ (or approx 5.6 Million Gallons)

- Total of water cost: 22,400 m_ X $1.5/m = $33,600

- Savings (40 percent) = $13,440

- These savings are conditional on a properly working Conductivity Control System.

c. Maintenance Cleaning

If not equipped by ATCS products, one needs to clean the cooling system periodically. This is done by dismantling system, draining, dismantling chillers/heat exchangers/condensers, manual scrubbing thenreassembling the system.

Maintenance cost of the cooling towers and condensers for a system size of 800 TR is about $7,000 annually.

d. Softeners and Chemicals

Industry estimates are that softeners cost is $0.45/m water used. In some cases the softening cost may be as low as $0.225/m, depending on water quality.

The yearly costs of softeners is approximately 7,000 Hours X 12.8 m/h make-up water X $0.225 to $0.45/m = $20,160 to $40,320.

(NB: Alternatively, one may use chemical treatment at a cost to the above system of approximately $10,000.)

2. Misc. Savings

The following are cost factors that depend heavily on system type, cooling power rating, application, etc. One cannot estimate their monetary value however users may do so, for their specific designed system and application.

a. Installation Costs

When a cooling system is installed, users must consider that it will not operate on, or close to, its rated capacity because of the fouling factor of the tubes. Design engineer will often attempt to forecast the rate of maintenance service and define a system which, at its lowest efficiency, will still satisfy user needs. Based on estimates of power loss due to scale or other fouling elements (see 1.a., above), one may have to specify a system which is up to 36percent larger than that required without consideration of the fouling factors. This constitutes a large difference in equipment and installation costs.

b. Down-time Costs

ATCS is an automatic, continual cleaning system. When equipped with ATCS the cooling system will operate continuously, as required, throughout the year.

When cleaned by the other methods, the cooling system needs to be taken down, drained, cleaned manually then reassembled again and restarted.

The down time is unacceptable to most applications. In order to be able to afford it, users many times install redundant capacity (to be employed when the main system is down). This constitutes a considerable additional equipment and installation cost.

c. Damage to the Environment

Chemicals leak to the environment with water. The damage to the environment cannot be taken lightly, although may be difficult to quantify monetarily.

d. Corrosion

Corrosion typically builds in systems that use chemicals and/or softeners. When using ATCS and SRS, the use of chemicals is reduced considerably and corrosion ceases to be a problem.

3. Summary of Quantifiable Savings

| Savings Item | Minimal Savings* | Maximal Savings* |

| Energy | 30,845 | 61,690 |

| Water | 13,440 | 13,440 |

| Maintenance Cleaning | 7,000 | 7,000 |

| Softeners or Chemicals | 10,000 | 40,320 |

| Totals** | 61,825 | 122,450 |

| *N.B.: not all users enjoy low costs on all items, so actual savings will most likely be in between the figures of these columns ** Net of non-quantifiable savings | ||

4. Cost of a typical system (such as C.Q.Ms ATCS and SRS) for the 800 TR cooling system:

- ATCS 3 x 6x $12,100 = $36,300

- SR systems 2 x $11,800 = $23,600

- Installation costs (at $1,200/system, typ. X 5 systems) = $ 6,000

- Total cost = $65,900