An organized, smooth-running MRO department can keep your entire company operating efficiently, whereas one that is disorganized, inefficient and ineffective can have negative ramifications that touch just about every aspect of your business , from overall productivity to employee safety to the bottom line.

Maximizing uptime requires both preventive and predictive maintenance, and both rely on having parts and materials on-hand and readily accessible. Disorganization means employees can't find the items they need when they need them. It is also a direct link to inaccurate inventories, unscheduled downtime, unexpected stock-outs, overcrowded or inefficient use of space, and mal- or non-functioning machinery.

If disorganization is a disease in your MRO department, an improved storage system is a likely cure. The benefits of implementing an advanced hardware and software storage system are many.

Zap it, map it, put it in a drawer

Consider stock options

In general, there are three types of storage systems to consider: conventional, automated and high-density.

Conventional storage, with principle components that include shelving, racks or bins, is most appropriate for bulky and/or slower-moving items. Pallet racks are used for items that are delivered on pallets or are heavy and must be moved by a forklift.

Automated storage and retrieval systems include horizontal and vertical carousel and lift systems, controls and software. These systems store a lot of items in a relatively small footprint, particularly the vertical systems. Vertical systems also offer exceptional security access, and so are well suited for the storage of valuable and/or limited access items, but are expensive and can require maintenance. They can slow down stocking and retrieval because they allow access by only one operator at a time.

High-density storage is well-suited for storing medium- to small-sized items. It includes modular drawer storage cabinets, mobile cabinets and other systems that feature sub-dividable drawers as their centerpiece. It offers benefits from complete use of cubic space to load capacity, and is typically more affordable than automated systems.

All these systems are most effective when combined with software to manage inventory levels and measure key performance indicators, which can help prevent breakdowns and predict future needs.

Where to put it all

It is important to set up a storage system correctly at the outset. Even the most sophisticated software and inventory systems are based on the principle of knowing where an item can be found and subsequently returned. Space planning is an essential first step, whether it's coordinated by your own staff, with the assistance of storage consultants or the manufacturers themselves. Taking advantage of free design-planning surveys from a manufacturer or its representatives can be a real cost-saver.

Both high-density and conventional storage can be stacked or used in mezzanines to take advantage of a room's full height and make maximum use of floor space. This can be a relatively inexpensive alternative to building an additional floor. Both can also be mounted onto a mobile aisle system, which is comprised of rolling rows of storage product with only one aisle accessible at any time. These space-saving systems eliminate wasteful aisles, but are not the best solutions for fast-moving inventory.

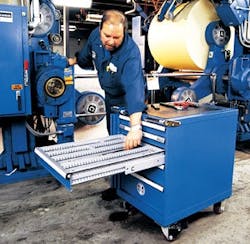

Mobile modular drawer storage cabinets deliver the flexibility and completely organized storage of high-density cabinets, while adding the benefit of convenience. With these mobile units, tools and parts can be rolled out directly to the job where they can be readily accessible to maintenance and repair personnel. These mobile workstations-on-wheels can be customized with the particular tool sets used by each craft. Repairs are performed more quickly, reducing downtime.

The best high-density storage solutions are modular, letting you select components that exactly suit your needs. For example, these can include cabinets of varied heights and widths, which offer many drawer height combinations. The modularity of these systems allows custom-fitted storage, and its interchangeable parts provide flexibility for future change and growth.

Modular high-density storage systems come in a huge range of sizes and shapes. You can also choose large wall units, which combine drawers, shelves and even rollout trays for storage of, and easy access to, heavyweight items. These units let you store large, medium and small items together: You can store according to need and craft versus storing merely by size. Such systems allow items in daily use (product that is broken down from bulk quantities to smaller, manageable quantities) to be mixed with bulk and slow-moving product for convenient access to both.

Another option is drawer storage units, which can be added into conventional shelving to provide a cost-effective way to improve existing storage without replacing it.

Mobile units can bring tools and parts directly to the job for ready access by technicians. Customize them with the particular tools of the craft to reduce downtime with fewer trips and quicker repairs.

The power of the drawer

Most MRO stockrooms are broken down into multiple crafts. Technicians who specialize in machine maintenance, plumbing or electric repair need storage that can be organized according to their tasks. Compartmentalized storage is important when you're dealing with such a variety of items, and is essential to fast access and efficient service.

The heart of high-density storage is the drawer, and not all drawers are made alike. The best make use of full cubic capacity while providing easy, direct access. Drawers should be able to handle a lot of weight -- some feature 440-lb. load capacity -- and even with this load, they should be full-extension to allow every inch of space used and easily accessed. Look for drawers that have full-height sidewalls and backs so that height, as well as width and depth, are available for storage.

Giving each part a "home" is essential for enabling MRO departments to function efficiently. Drawers that are easily sub-dividable into compartments allow such separation of individual parts. Good drawer dividers allow easy identification of compartment contents and provide for bar code labels.

To more clearly understand the advantages of high-density storage, compare it to the conventional shelving alternative:

* High-density drawer storage uses all available cubic space and frees up floor space; conventional shelving, on the other hand, can waste as much as 80% of that cubic space while consuming floor space.

* Full-extension drawers provide easy access. Upper levels and the rear of conventional shelves are hard to see and reach, and often wind up unused. Items on shelves are often stacked, are difficult to retrieve and easy to lose.

* Inventory control is easy in compartmentalized storage because there is clear visibility. Shelving provides no efficient parts location system.

The primary mission of MRO personnel is to maintain and repair equipment to keep the company operational. Organized tools and parts are essential to an MRO department's success. To minimize downtime, and maximize productivity, consider the storage options that promote the highest degree of organization. When your MRO department is in need of a little "preventive maintenance," the right storage solution could be just the medicine you need.

Top 10 reasons to get organized

1. Reduce downtime.

2. Raise workforce productivity.

3. Improve operator safety with properly operating machines.

4. Reduce product defects.

5. Reduce inventory due to greater visibility.

6. Improve reorder efficiency with accurate min/max quantities.

7. Make the inventory process faster and easier.

8. Pick parts faster with safer ergonomics.

9. Improve the use of valuable floor space.

10. Improve plant aesthetics and raise your professional image

John Alfieri, vice president, sales and marketing, Lista International Corp.,

Figures: Lista International