Recent lighting technology improvements have increased overall system performance for some high intensity discharge (HID) and fluorescent systems, making it possible to reduce lighting energy bills, improve light quality and enhance overall operating results.

Background

Lighting designs for industrial and warehouse applications are based on several factors, including safety, energy cost, maintenance cost, quality of light and lighting uniformity. The most important of these depends on the specific lighting application. For example, some industrial environments involve inspecting colored textiles, which requires either good color rendering from a general lighting source or supplemental task lighting with the proper color quality. A source with a lower color rendering index (CRI) may suffice for a warehouse application where seeing true colors is not important. Each design factor contributes to a facility's overall operating results.

Cost reduction and cost avoidance are achieved in several ways. Long-life light sources reduce maintenance costs and cause fewer work interruptions. Uniform light levels with good color quality may improve plant productivity, reduce lost-time accidents, increase worker morale and improve a plant's image. Energy-efficient lighting affects energy costs. These attributes can improve operating results.

|

View more lighting content on PlantServices.com |

Table 1: T8 and T12 system comparison.

T8 fluorescent for task lighting and lower ceilings

Most industrial or warehouse facilities use HID lighting for higher ceilings and fluorescent lighting for lower ceilings and task lighting. In many cases, task lighting scattered throughout a facility increases or improves the lighting in specific small areas that require different lighting than that provided by the general lighting. For lower ceiling and task lighting applications, T8 fluorescent lamps on electronic ballasts have been shown to improve lighting efficacy and quality over T12 fluorescent lamps. Table 1 shows the energy efficiency improvement of T8 lamps on electronic ballasts as compared to T12 lamps on magnetic ballasts.

The last column represents a 30 W T8 energy-saving retrofit lamp. It operates on existing instant-start T8 electronic ballasts as a direct retrofit for standard T8 lamps. It saves approximately 1.5 watt per lamp over a standard T8, while providing slightly higher lumen levels. At $0.10/kWh, the 1.5 watt per lamp results in $2.70 in energy savings per lamp over its life. In recent years, other higher output, energy efficient, longer life T8 lamp and electronic ballast systems have been introduced. For further information about energy-efficient T8 fluorescent systems, contact a lighting engineer or energy service company.

High bay general lighting

High bay lighting is used when ceiling height is greater than 20 feet. These applications most often use metal halide or high-pressure sodium for the high wattage availability and high lumen ratings to achieve cost-effective lighting using a minimal fixture count. Fluorescent lamps are a diffuse source with lower wattage and lumen ratings than high-watt HID sources, making them ideal for lower ceilings. However, new high-efficiency linear fluorescent lamps are now useful in high ceiling applications.

High-pressure sodium lamps

High-pressure sodium (HPS) lamp systems have long life ratings and a high lumen per watt rating, but have a yellowish color. Most HPS lamps have a color rendering index of approximately 22 on a scale of 100, which prevents accurate object identification on the basis of color alone. For this reason, HPS lamps generally have been relegated to outdoor area lighting or to warehouse space where color identification is irrelevant.

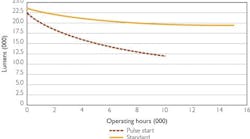

Figure 1. Lumen maintenance of standard 250 W MH versus 250 W pulse-start MH.

Metal halide energy saving retrofit lamps

Metal halide lighting offers long life, good color rendering, good efficacy and consistent performance at any temperature. Two product families offer improved lamp efficacy. The simplest is the energy-saving retrofit, such as a 360 W metal halide lamp that operates in standard 400 W M59 fixtures. These lamps have life and lumen ratings equivalent to standard 400 W MH lamps, but operate with a 40 W savings. The first cost for a conversion to 360 W units includes only the lamp, as no fixture or ballast changes are required. At $0.10/kWh, energy savings over standard 400 W metal halide lamps equates to $80 per lamp over the 20,000-hour lamp life.

Metal halide pulse start lamps

Higher wattage pulse start metal halide lamps were introduced in the mid-1990s. Lamp and ballast design changes reduce lumen depreciation, which gives lower-wattage lamps mid-life and end-of-life lumens similar to higher-wattage lamps. Because pulse start metal halide lamps operate on different ballasts than standard metal halide lamps, they are not a true retrofit product. It often makes more economic sense to replace entire fixtures with a lower-wattage pulse start system and a more efficient luminaire to maximize system performance using a lower-wattage lamp.

Major lamp manufacturers are testing high frequency electronic ballasts for use with pulse start metal halide lamps. Preliminary results promise even greater improvement in lamp life and efficacy.

Multi-lamp fluorescent systems

High bay lighting systems using multi-lamp fluorescent lamps and high-efficiency luminaires also offer energy-saving improvements. Multi-lamp fluorescent fixtures often are more expensive than HID fixtures, but long-term efficacy and occupancy sensors can make them more cost-effective in the long run. New fluorescent lamps offer good-to-excellent CRI, dimming flexibility, long life and excellent lumen maintenance. Their nearly instant-on and instant hot restrike capability make them suitable for many traditional HID applications. Table 2 details data for the most commonly available high bay lighting systems. In each case, lower-wattage pulse start metal halide systems and multi-lamp fluorescent systems have lower initial lumens than the 400W metal halide system. However, the maintained lumens will be equivalent.

Several important points apply to Table 2. First, the baseline used was an inefficient 400 W metal halide system. There are more efficient metal halide lamps and fixtures available, but they're rarely used in older installations. Second, the table assumes converting to a lower-wattage pulse start metal halide system also would involve changing to more efficient luminaires. Third, lamp life ratings are not identical for every system. For example, the 42 W compact fluorescent lamps have a life rating of 10,000 hours. Most other types on the chart have a lamp life rating of 20,000 hours. Fourth, T5 fixture efficiencies of near 100% are achievable only because T5 lamps operate at higher efficacies inside the warmer fixture than in open air.

Table 2: Comparison of various high bay systems.

Manufacturers generally publish lumen ratings for T5 lamps at both 25 C and 35C. The high fixture efficiencies of near 100% are the result of using the lower rated lamp lumens at 25 C ambient. One can't make a fair and accurate system comparison by using both the higher lumen rating of T5 (at 35 C ambient) and the near 100% fixture efficiencies published by the luminaire manufacturers. Finally, the luminaire efficiencies and lamp lumens in Table 2 are typical values. The exact values vary according to manufacturer, so it pays to consult the published literature for more accurate information.

Metal halide and fluorescent systems offer energy savings potential, but Table 2 doesn't tell the entire story. Cold storage areas or unheated spaces in northern climates may require the most energy-efficient metal halide systems with its stable, temperature-insensitive light output and efficacy. T8 and particularly T5 fluorescent lamps may exhibit a large lumen and efficacy reduction if operated in cold temperatures. Conversely, a fluorescent system would be preferable for installations with occupancy sensors used to reduce energy use.

Metal halide lamps can be dimmed to 50% power, but they can't be shut off with occupancy sensors. Once extinguished completely, metal halide lamps require five to 12 minutes to cool down and restart. Furthermore, once ignited, it may take one to three minutes to achieve full output. Fluorescent lamps are instant-on and instant restrike, making them suitable for use with occupancy sensors.

Improvements in metal halide, compact fluorescent, T8 and T5 linear fluorescent lighting, electronic ballasts, and luminaires have presented opportunities for upgrades to save energy. In some cases, payback can be less than one year. In most cases, it's less than three years. Contact a lighting engineer for a more complete list of energy-efficient lighting options.

Bob Ponzini is a commercial engineer at Osram Sylvania. He can be reached at [email protected].

Figures: Osram Sylvania