Derived from the Italian "terrace," terrazzo is a mosaic floor made by embedding small pieces of marble or granite in mortar and polishing the surface.

|

View more flooring content on PlantServics.com |

Today the definition of this traditional material has changed. Terrazzo is a composite material poured in place or precast and typically used for floor and wall treatments. It consists of marble chips or other aggregates combined with a binder or matrix. The terrazzo is poured, cured and, in most installations, ground and polished.

The chips used in terrazzo include any calcareous, serpentine and other rock capable of being ground and taking a good polish, such as marble and onyx. Other materials that don't require polishing, including quartz, granite, quartzite and silica pebbles, are suitable for rustic terrazzo finishes. The chips are mixed with a Portland cement or resin binder to achieve a minimum of 70-percent chip density on the surface.

Three types of matrices can anchor the aggregate in a terrazzo floorcementitious, polyacrylate-modified cement and epoxy.

The cementitious matrix is either white or gray Portland cement. White Portland cement is more widely used because its color is controlled precisely during manufacturing, and it can be combined readily with tinting pigments to provide a clear, uniform color.

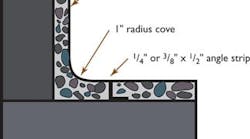

A modified-cementitious (polyacrylate) matrix is a composition resinous material that is an excellent binder for thin-set terrazzo. A thin-set terrazzo system can be applied in a thin cross-section (3/8 inch or less) over concrete or other suitable substrate. This matrix uses Portland cement and a latex additive that fortifies and strengthens the floor. Polyacrylate matrices can be colored in the same manner as the cementitious variety.

Epoxy is a two-component, thermal-setting resinous material that is also an excellent binder for thin-set terrazzo. Epoxy resin terrazzo floors contain special chemical matrices that make them resistant to harsh chemicals. They offer an infinite number of color formulations. Because of their light weight, epoxy terrazzo systems are used extensively in multi-story buildings and renovation projects. They require no special elevation adjustments or structural modifications.

Laying the floor

Most terrazzo systems are poured in place, ground to a flat surface and polished to reveal the natural color and beauty of the aggregate. On the other hand, the rustic variety, a cementitious form of terrazzo, requires no grinding. Instead, the topping is washed or treated to expose chips, which produces a uniformly textured surface. Exterior work where the rustic terrazzo will be exposed to freezing conditions requires a dense chip and a matrix containing a suitable air-entraining agent.

An epoxy terrazzo flooring system works best anywhere a monolithic, virtually indestructible floor surface is needed. In food plants, kitchens, cafeterias and other areas where exposure to microorganisms is an everyday occurrence, epoxy terrazzo flooring systems are the ideal. The epoxy matrix that binds the materials doesn't support biological growth. Furthermore, microorganisms require a nutritional carbon source to grow, and because an epoxy matrix contains no carbon, growth can't be sustained, and the microbes die; therefore, adding bacteriostatic and fungi-static adjuncts to the matrix is unnecessary. This sanitary, smooth, joint-free monolithic surface can be cleaned easily with a mop and water.

Degrees of separation

In most cases, dividing strips are used during the installation of terrazzo (see Figure 1). They enhance and highlight color patterns. Available in zinc alloy, brass, black and white or colored plastic, divider strips complement the terrazzo floor. They may be specified in custom sizes, shapes and even intricate configurations to produce beautiful and unusual designs, color effects and corporate logos. Used not only to enhance or highlight color patterns, the divider strips also serve as a control for anticipated contraction, a leveling device and a crack preventer.

Divide and control

Figure 1. Divider strips can beautify floors as well as provide contraction, level and crack control.

Precast terrazzo

Because of their intricate shape or the building's design elements, custom terrazzo items, such as stair treads and risers, window sills, bases, thresholds, outdoor furniture and other architectural details, are sometimes precast (see Figure 2). Precast terrazzo items are poured into molds and then moisture-cured, ground and polished or otherwise finished.

Despite high initial cost, terrazzo offers long-term value. As the initial investment is amortized over time, its longevity reduces its life cycle cost with every passing year. A terrazzo floor has a life expectancy that is, in some cases, longer than that of other structural elements in a building.

A place for precasting

Figure 2. Intricate or custom items such as stair treads, sills, bases and thresholds can be precast for easier installation.

Terrazzo is a signature material. It allows the freedom to create detailed and multicolored designs while still maintaining a seamless surface; one that is durable, easy to maintain and truly unique. While beauty and durability are still important, today's designers, architects and building owners are also keenly aware of the economy and performance of their flooring system. In fact, an epoxy terrazzo flooring system installed 20 years ago can look as good today as a newly installed system.

Care and maintenance

To best understand terrazzo, look at its componentsaggregates and binder. These components are mixed at a ratio of 2 to 1 (chips to binder). During installation, additional chips may be sprinkled on the surface so that a minimum density of 70-percent marble chips appears on the finished surface.

When maintaining terrazzo, the use of a pure surface coating (as most floor waxes are) is unnecessary and ordinarily not recommended. The surface is at least 70 percent aggregate. Applying a surface coating or wax may decrease the non-slip characteristics by reducing the coefficient of friction to below the standard rating of 0.5.

The aggregates have low porosity and don't absorb most staining substances. The portion of the terrazzo that needs protection is the binder, especially cement, which is porous and will absorb stains. Terrazzo doesn't need protection from wear; it needs protection from absorption, and this is achieved through the use of penetrating sealers that seal the pores in the binder. The only maintenance necessary is the periodic application of a sealer having a non-slip rating of 0.5 or greater.

Terrazzo should be cleaned only with liquid cleaners having a pH between 7 and 10. The cleaner must be free of harsh alkalis that might damage the floor.

To clean terrazzo, mop the cleaning solution onto the floor and give it several minutes to dissolve the grime. Then simply squeegee, wet vacuum or mop up the dirty solution. Keep the floor wet during the entire cleaning process so the dirt won't reabsorb into the floor.

If a mop dressing is used for daily sweeping, be sure it's non-oily. Most sweeping compounds contain oil (a fire hazard) and sand, which is hard to sweep up and can abrade the floor.

Curing and asthetics

A new terrazzo floor requires time and patience to allow the curing process to run its course. It's also true that many terrazzo colors will appear mottled initially. This does not indicate poor installation. It's a function of the normal characteristics of the system. The initial perception of a new terrazzo floor may not be exactly what is desired, but it's predictable that with each passing day, the aesthetics increase, and the results of a good installation will become apparent.

Terrazzo flooring systems are suitable for any commercial, industrial or institutional application that requires a monolithic, virtually indestructible floor surface. An epoxy-based system can withstand continuous heavy traffic and is resistant to water, chemicals, oil, grease, most acids and solvents. Epoxy terrazzo's sanitary, smooth, joint-free monolithic surface won't absorb germs and bacteria.

Terrazzo floor coverings can truly be works of art. With the imaginative use of divider strips and color variations, designs, logos, words and other configurations become a permanent part of a building interior design plan. The design flexibility of terrazzo flooring systems is only as limited as one's imagination.

Terri Sparks is the Co-Chairman of the National Terrazzo and Mosaic Association's Promotional Committee headquartered in Purcellville, Va. She can be reached in Wheeling, Ill., at [email protected] or 847-777-6778.

Figures: National Terrazzo and Mosaic Association

Photos: Michael Woodall