Single-point automatic lubricators can take the guesswork out of bearing lubrication

Actually, asking "What's wrong with the lubrication I'm using?" may be the wrong question. A more appropriate question might be "Is my lubrication being applied correctly?" In fact, more maintenance departments are recognizing that "how much" and "how often" are just as important as "which type." That's why single-point automatic lubricators take the worry and maintenance out of bearing lubrication.

Often, the name of the game in manufacturing productivity is preventive maintenance; that is, carrying out economical maintenance now to prevent equipment breakdowns before they occur. Considering that nearly 90 percent of bearings are lubricated with grease, and 80 percent of bearing failures are lubrication related, a crucial aspect of preventive maintenance is ensuring that bearings are maintained at proper lubrication levels, with adequate grease to help keep out water, dust and other contaminants.

Unfortunately, lubrication is not the highest priority on some maintenance agendas, a situation often attributed to the potential danger in trying to reach relatively inaccessible bearings on operating equipment. It's oftentimes justification enoughin the eyes of somefor bearing lubrication to be neglected. At the same time, proper grease quantities can be a nagging problem, with over-greasing or under-greasing potentially causing a bearing failure.

Three paths

For the most part, three basic approaches provide lubrication; manual methods, centralized lubrication systems and single-point automatic lubricators.

Manual lubrication sounds simple enough in theory, yet carrying it out properly and reliably is not as simple as you might think. The maintenance technician must be diligent to ensure each bearing receives the right amount of the right grease at the right time. Manual lubrication is costly because it requires a person dedicated to the task.

Centralized lubrication systems are more reliable, but expensive. They're cost-effective when numerous lubrication points in close proximity require the same grease.

Automatic lubricators

Automatic lubrication devices guarantee a lubrication schedule and introduce only fresh lubricant. From a maintenance-engineering standpoint, the benefits of a single-point automatic lubricator include:

Guaranteed continuous and controlled lubrication flow.

No temperature increase during lubrication.

Continued lubrication in dangerous areas while machines operate.

No foreign particles in lubrication lines.

Lubricated bearings in hard-to-reach, forgotten areas.

Longer maintenance intervals.

Reduced grease consumption through more efficient lubricant use.

Longer operating runs and decreased downtime.

Quick return on investment from reduced repair and maintenance cost.

Electrochemical units

Turning an activator screw in the rear of an electrochemical lubricator drops a pellet into a liquid electrolyte. The harmless gas evolved in the resulting chemical reaction inside the housing pressurizes a bladder and piston to as much as 65 psi, which tries to dispense 120 cc of grease into the lubrication point continuously. The grease flow is retarded by additional activating screws that allow for precise lubrication dosage during a one, three, six or 12-month period. The activation screws, as well as the ambient temperature, determine how rapidly the chemical reaction builds pressure and, therefore, how quickly the lubricator is exhausted. At that time, the unit is discarded as any other non-hazardous item.

Fitted with a clear plastic housing, the unit meets food industry washdown requirements. However, the plastic is gas-permeable and should not operate for more than six months.

When to use gas-driven units

Gas pressure and expansion rate are functions of ambient temperature. Hot gas tries to expel grease at a faster rate than cold gas. Activating screw settings compensate for temperatures from -13 F to 104 F. Although gas-driven units can function in virtually any positionincluding under water and in explosion-proof environmentsthe remotely mounted type can extend no more than six feet from the lubrication point.

Electromechanical units

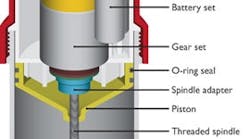

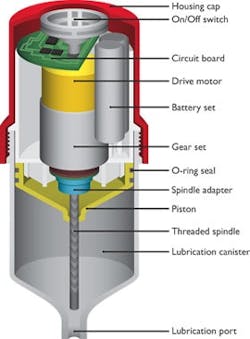

An electromechanical lubricator is a reusable, battery-powered, motorized unit with a replaceable lubrication canister. It features adjustable discharge periods and can be turned on and off with a switch. When activated, the motor powers a gear set that turns a threaded spindle to drive a piston that pressurizes the grease to 75 psi. Electromechanical unit performance is temperature-independent and discharge periods are more precise than with the electrochemical units.

The unit has two DIP switches: the settings on one correspond to the size of the grease cartridge while the second regulates the discharge duration. An illuminated LED indicates error-free operation. The electromechanical unit's self-check capability issues warnings when it's empty or has a problem delivering grease. Motor-driven automatic lubricators ensure a reliable discharge cycle and predictable grease quantities.

As an example (see Figure 1), a unit with 120 cc of grease might be programmed for three months of lubrication, and set to discharge grease every 4.5 hours, or roughly 1.33 cc of grease per day. When done properly, a little lubrication goes a long way. Yet, strategically, more frequent lubrication with lesser amounts could conceivably minimize friction and help reduce heat build up. Automatic and precise grease delivery produces many benefits, the most important of which are extended bearing life and reduced downtime. An electromechanical lubricator (See Figure 2) can be mounted in any convenient location as far as 12 feet from the bearing, although generally it must be installed upright in non-hazardous environments.

Figure 1. Motor-driven automatic lubricators provide reliable discharge cycles and predictable grease quantities.

Automatic lubricators can service anything that requires a steady flow of grease, and even can be used as a miniature central lubricating system delivering grease to multiple points.

Figure 2. Cross-section of an electromechanical lubricator.

Adjustable lubricators

Work to enhance automatic lubricator efficiency and convenience continues. A system currently under test enables these relatively inexpensive devices to "read" a lubrication scenario and adjust grease delivery accordingly. The advantages are obvious, including worry-free maintenance and longer service life for bearings and operating equipment.

The design and reliability of today's automatic, single-point lubricators make them an important component of preventive maintenance. These devicesno longer limited for use in hard-to-reach areas, but rather, in critical lubrication areas as welloffer simplicity and long-term cost savings. They provide maintenance personnel with the kind of flexibility and choice that make decisions easier and more timely.

Frank Mowka is an applications engineer at FAG Bearings Corp.

Figures: FAG Bearings Corp.