Cogeneration can help be a long-term energy-producing alternative

Cogeneration, satisfying simultaneously an electrical power demand and a prescribed heat load, is an attractive long-term energy-producing alternative, particularly given energy price volatility and the vulnerability of the power grid. If your plant can use a gas turbine as the prime mover, opportunities exist for improving energy utilization, and with it, overall operating efficiency and reliability. The advantages go well beyond the individual facility. Cogeneration is applicable to a range of manufacturing facilities and heating applications that include steam production, drying and absorption chilling.

Cogeneration advantages

Power reliability is cogeneration's greatest benefit. No plant can afford blackouts from storm damage, poor utility operation or transmission line failures. Onsite cogeneration systems equipped with sufficient redundancy, such as standby grid connection and uninterruptible power supply systems, can far exceed the reliability of some local utilities.

In addition, unpredictable power surges, drops and voltage sags can damage computerized systems and sensitive electronic equipment. On-site cogeneration significantly improves power quality. Gas turbine generators typically provide constant voltage and current without the peaks and interruptions so often found on the grid.

There are environmental benefits as well, including improved overall efficiency and reduced air emissions. Cogeneration offsets other forms of energy production, such as power grid generation and localized firing of natural gas or diesel in a boiler. According to the United States Department of Energy, cogeneration systems can reduce annual greenhouse gas emissions by at least 25 million tons of carbon if the government's goal of doubling installed cogeneration capacity in the U.S. is accomplished by 2010. Overall emissions of carbon dioxide, oxides of nitrogen and sulfur dioxide from grid-provided electrical production are reduced as more onsite cogeneration systems are installed.

Recovering useful heat

The facility heat load is the more critical variable, despite the obvious need for generating electricity. Because the heat load must be satisfied with a steady stream of hot exhaust gas, the heating load profile must be understood clearly, and demand must be matched to the load using an exhaust bypass for low-load conditions and supplemental firing for high loads. Similarly, local utilities can supplement electrical demand during power shortfalls, and excess can be sold back to the utility during periods of low electrical demand.

Economics favor systems that operate at least 8,000 hours per year and have substantially constant heating loads. Facilities that attempt to apply cogeneration to variable process systems, such as steam heating or direct drying, often discover that matching a variable heating profile can be difficult. Such variability should be identified early and predicted at the design stage.

System alternatives

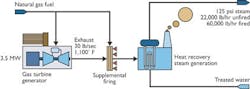

The most common way to apply cogeneration is by using a gas turbine as the prime mover and a heat recovery steam generator. Figure 1 shows an open-loop system that uses all available steam without having to return condensate to the boiler. The application works best for continuously operated facilities that use steam year-round.

Figure 1. An open-loop steam system for a cogeneration plant.

An example of a closed circuit application is a district heating/ cooling system for a college campus. In this case, condensate is reclaimed and fed back to the boiler for steam production. Several dozen systems in the U.S. have successfully applied cogeneration to provide power, steam and cooling streams in a central plant. As an example, one facility installed a 42-megawatt (MW) gas turbine cogeneration plant to serve its energy needs. The steam is produced at the desired pressure and at a flow rate equivalent to the heat recovery ability of the steam generating equipment. Supplemental firing increases the steam flow to satisfy peak demands or simply to meet higher sustainable heat loads. The steam can be used for a heat-only application, or the excess can be directed to an absorption chiller to produce chilled water.

Project evaluation

Justifying the cost of a cogeneration system requires a detailed evaluation of its technical and commercial aspects. When considering the electrical demand of a potential cogeneration site, ensure that the buy-back rate the local utility company offers is attractive for a slightly oversized cogeneration plant. Avoid a significantly oversized cogeneration plant because utility rates may be renegotiated several times during the plant's life cycle, and changes to the buy-back rate may produce an unfavorable operating profile.

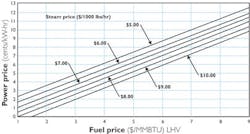

Ensure that local power rates are high in relation to the cost of natural gas.

The differential, or spark-spread, has a significant effect on project economics. Assess fuel availability and price, both now and in the long term. Establish the unit value of steam based on existing equipment operation. Once the power, fuel and steam pricing are known, use Figure 2 to determine whether a five-year breakeven is possible. Economically successful cogeneration projects typically have shorter paybacks.

Figure 2. Determine whether a five-year breakeven is reasonable.

Determine the average thermal and electrical loads and perform an energy analysis.

Facilities with larger power and heat loads can generate proportionately greater savings and a shorter payback period. Ensure that the power and heat loads are simultaneous. Other evaluation parameters to consider include the following:

Calculate the plant's expected heat-to-power ratio.

Ideally, the facility's heat sink should provide a minimum ratio of around two kW of heat for every kW of electrical power. Higher ratios can be satisfied with supplementary firing. Lower ratios indicate insufficient use of gas turbine exhaust heat and may require a bypass stack to dump unused heat.

Verify the pressure in your natural gas supply.

If only low-pressure gas is available, additional investment in a compressor to boost gas pressure to approximately 200 psi will add cost to the project, as well as increase maintenance and operation over the plant's life cycle.

Assess the future energy demand over the expected life of the cogeneration plant.

The ability to expand capacity to meet future loads can further justify cogeneration.

Evaluate the facility's operating profile.

Take into account the necessary scheduled maintenance outages and possible unscheduled events.

Provide for a backup source of power to ensure continuous supply.

One way to do this is through a standby contract with the local utility company, which allows power to be accessed from the grid during outages.

Keep in mind that gas turbine generators, heat exchangers, switchgear, control systems and emission-control equipment require sufficient real estate. Determine the tie-points between the plant and the proposed cogeneration plant.

Assess local and state environmental and air-quality requirements for gas turbine exhaust.

Many states require very low NOx and CO emissions, which means that installing selective catalytic reduction systems and CO catalysts in the exhaust stream add significant cost to a project.

Finally, obtain firm quotations for equipment procurement, engineering activities, construction and startup.

Minimizing the risk of project overrun is essential in making the economic assessment viable.

Project development

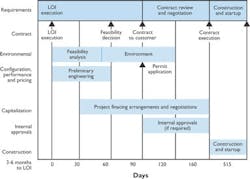

The execution of a cogeneration project is similar to that of other equipment-intensive capital projects, although there are some unique factors to consider. In particular, pay close attention to obtaining environmental permits, such as Air Quality Title V permits. Government and public applications reviews can add significant time to the project development schedule. Allow enough time to evaluate project economics and financing, particularly when dealing with highly volatile inputs, such as gas and power prices.

Figure 3 illustrates a typical cogeneration project development timeline. Beginning with a letter of intent, a realistic time frame between developing the overall project and commercial operation is as long as 18 months. Activities related to evaluation, permitting and contract negotiation can consume at least six months, followed by another year of engineering, procurement and construction activities.

Figure 3. Typical development timeline.

Cogeneration has potential in almost every industrial and commercial setting. In many cases, the economic and operational benefits of cogeneration far outweigh the cost and effort of developing and maintaining a cogeneration plant.

Tim Baur, P.E. is the Industrial Program Manager at Vericor Power Systems LLC in Alpharetta, Ga. He can be reached at [email protected] and (770) 569-8800.