Across the nation, chimneys and stacks rise from industrial facilities like monuments to American industry. But unlike monuments, they are designed to last the life of the plants they serve, usually 25 to 30 years. Their useful lives are determined by their environments. With the right care and maintenance, however, most can continue to serve for years beyond their intended life spans.

Whether it's a simple unlined steel stack or a complex chimney with a reinforced concrete shell surrounding one or more flues, common factors contribute to deterioration. Their sheer height, slender form and unique function create an environment quite different from that of other structures,one where degradation is accelerated and hazards magnified.

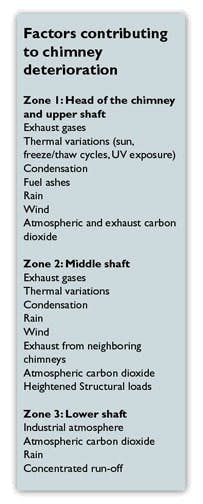

To better understand the factors that cause deterioration, divide the chimney into three sections or zones. Each zone is subject to common deterioration factors, as well as some that are unique to it.

Causes and effects

Chimneys begin to deteriorate from the moment they're built, and before they're put into service. The pace of deterioration is exponential. In the early years, no signs are apparent. In subsequent years, however, deterioration accelerates rapidly, often catching facility managers off guard and requiring major repairs instead of minor maintenance. Without an adequate maintenance program, deterioration is inevitable.

Reinforced concrete chimneys have three major causes of deterioration. The first is from the flue gas itself. Combustion of sulfur-containing coal and oil produces corrosive forming components that attack the calcium silicate hydrates that give strength to concrete. Gases bleeding into the annular space between the liner and chimney shell condense and form an acidic liquid. If it reaches the reinforcing steel, corrosion-induced cracks, delamination, and spalling result.

A second form can occur when the liner itself begins to deteriorate, and the chimney is exposed to the hot gases directly. Metal liners have either an exterior liner insulation to maintain a "hot side" temperature above the dew point of acid gases or an interior acid-resistant coating. If the insulation becomes damaged or saturated, or the original acid-resistant coating material fails, holes will develop in the liner, allowing the process gas to come into direct contact with the chimney shell. At that point, the stress is both chemical and thermal. Thermal stress causes the concrete to crack and spall.

The third form relates to carbonation. When the concrete is exposed to carbon dioxide continuously, its pH declines, reducing the protection it offers to the embedded steel reinforcing.

In many chimneys, carbonation proceeds at a rate of approximately one-millimeter per year,hardly significant. However, in 25 to 30 years, as much as 1.5 in. of concrete will have been carbonated. This is particularly troublesome because the outer curtain ring of reinforcing steel is embedded beneath only 1.5 in. of concrete, which leaves it exposed to corrosive elements.

When reinforcing steel rusts, it undergoes a volumetric change,sometimes expanding 12 to 14 times its original size. This causes the concrete to spall and fall off. Carbonation occurs more rapidly at cracks and construction joints, and where heat is applied.

Some facilities use wet scrubbers to remove sulfur compounds from flue gases. The scrubber residue combines with water to form sulfuric acid, which is extremely corrosive to most metals.

Weather plays a role

Don't underestimate the effects of wind, rain and fluctuating ambient temperatures. While it's true that structures exposed to dramatic seasonal fluctuations are at a greater risk, no facility is immune to the effects of environmental forces.

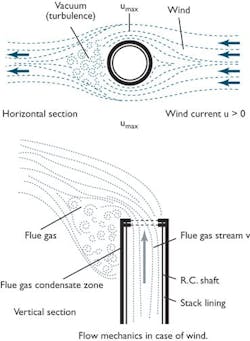

When wind velocity is greater than zero, an airflow pattern develops around the stack quickly. Figure 1 shows the effects of a positive wind velocity. Aerodynamic volume displacement increases wind velocity around the stack. This produces a zone of negative pressure on the leeward side, and draws in the flue gas. Because the shaft surface temperature is much lower than that of the emerging flue gas, condensation occurs on the leeward side, leaving yellow, brown or black deposits.

Construction techniques

Chimney construction techniques also lead to deterioration. Reinforced concrete stacks as high as 500 ft. are stage-built in 7- to 10-ft. sections. As a result, cold joints between sections hinder proper concrete bonding. This creates a path for air and water to attack the reinforcing steel where it bisects the construction joints. Furthermore, the sand and cement that covers the joints lasts only five to seven years before it weathers away, creating a pathway for corrosive elements. This can result in structural deficiencies.

With metal stacks, which are often designed for a height less than 200 ft., the steel is welded and exterior stiffeners are added. Weld joints can suffer from small cracks caused by wind loads and thermal stresses during construction. Once a crack begins, corrosion soon follows. It usually develops in places hidden from the eye.

Performing structural repairs is something that many facility managers don't wish to contemplate. For reinforced concrete chimneys, for example, structural repairs usually entail exposing and blast-cleaning the reinforcing steel, chiseling-off unstable component parts and sandblasting foreign matter. This must be completed before applying new concrete and protective coatings.

Coatings to the rescue

A variety of coatings are available for chimney protection. Some are quite specialized, and are able to withstand a range of thermal conditions.

Concrete chimneys are coated for three reasons:

- Protection against environmental elements.

- Protection against process gases.

- Compliance with Federal Aviation Administration requirements (flashing lights for nighttime, warning paint for daytime).

To select the most appropriate coatings, consult a chimney expert and not merely someone with a knowledge of paints and coatings. For example, an acrylic-based aviation warning paint is sufficient and provides proper visibility for seven to 10 years. However, in some situations, aviation warning paint doesn't provide the proper resistive qualities and doesn't seal construction joints properly, which can lead to future deterioration and costly repairs. In such cases, a chemical-resistant epoxy coating is applied to the upper chimney zones, while a less resistive (and less expensive) coating suffices for the lowest zone. Some facility managers apply the resistive coating to the entire chimney, because rain flushes corrosive materials from the higher zones.

The effects of wind on chimney deterioration can be significant. A zone of negative pressure develops on the leeward side of the stack, causing wind turbulence. Flue gas,containing potentially corrosive compounds,is then drawn in to this area.

Illustration courtesy of Robert Engelfried, University of Dortmund, Germany.

View the variables

It's important to consider more than just the chimney's exterior when selecting coatings. For example, some liners are located close to the shell, which transmits more heat. In such cases, make a provision for the concrete to "breathe," and pass through the moisture vapor. If the coating prevents breathing, the trapped moisture corrodes the reinforcing steel. To prevent this, a breathable epoxy coating with a urethane topcoat is often a good solution, provided it's compatible with the heavier-bodied material used to seal joints.

Coatings protection also applies to the chimney flue or liner. Research chimney operating conditions carefully. Sometimes specifiers make the mistake of only considering the process gas temperature as it exits the boiler or the scrubber. Consider other temperatures, such as those that occur during start-up and by-pass, before making your selection.

Using only the normal online temperature can also be a mistake, because the insulated steel liner surface temperature, which normally remains above the dew point, may not behave as expected. Temperatures inside the chimney fluctuate,especially during startup or shutdown operations. These fluctuations increase the probability of acid condensation.

Alternate coatings for metal stacks are available. They have a higher interior and exterior heat resistance, and are made from vinylester and phenolic compounds, as opposed to acrylics and enamels. Another coating "metalizes" the stack's interior by applying a pressurized molten zinc or aluminum alloy, which enhances cathodic protection during high-temperature operations.

Be proactive

By the time you notice a problem, you're already moved beyond the realm of maintenance and into the hapless region of "costly repair."

What's the best approach to minimize the risk of a costly repair or rebuild? Start by shifting the focus from short-term maintenance costs to long-term lifetime cost. Examine the original chimney design drawings. Learn what you have in terms of stacks, liners and coatings. Especially focus on the interface between the liner, side clearances and other elements.

Sometimes, internal maintenance staffs can create bigger problems than they solve by performing "patch" repairs. These can upset the delicate balance between liner and shell. Both items should move independently to prevent mechanical stresses of the wind and sun on the column (which is designed to accommodate them) from being transferred to the liner (which is not). Also, many repairs weld fresh material to cover a hole, only to damage the interior coating during welding.

Furthermore, don't settle for testing only one portion of the structure for corrosion. Also perform a hammer inspection of the chimney shell. Determine a baseline, and then review conditions every 24 to 36 months. Performing minor caulking and painting over time reduces the probability of incurring major problems and repairs.

Many companies are outsourcing chimney maintenance. This allows for predictive planning and budgeting. An outsourced program will begin by establishing a maintenance history on the chimney, which is valuable reference in subsequent years.

Above all, don't rely on past levels of inspection and maintenance activities to determine future actions. Chimney deterioration is notorious for its ever-accelerating rate. Just because inspections have been spotty historically does not mean that greater vigilance is unnecessary now.

J. R. Biggs is a regional manager of Maintenance & Repair Services at Pullman Power, LLC, a subsidiary of Structural Group. Biggs can be reached at (816) 231-7400 or at[email protected].