In brief:

- One advantage of Foundation Fieldbus is that it’s a continuously evolving specification.

- The Fieldbus Foundation updated its specification in August 2010, to incorporate NE 107, and it’s supported in Version 6.0 of the Interoperability Test Kit.

- A series of new field diagnostic alarms correspond to the five primary diagnostic categories NAMUR outlined.

We’ve said for a long time that the real economic benefits of fieldbus come in the operational phase of the plant. Foundation Fieldbus-compatible devices can provide a wealth of data both about themselves and about the process that can be turned into useful information. Sometimes, however, turning all the data and getting it to the right people at the right time can be a challenge.

The Fieldbus Foundation realizes this, and several years ago we began cooperation with a European end user group called NAMUR (www.namur.de) to provide more information in context to operations and maintenance. For those that are not familiar, NAMUR is a group comprised solely of end users and systems integrators in the European process industries. NAMUR represents approximately 15,000 process control experts, of whom approximately 300 are active in 33 working groups. NAMUR pools their experience to create best-practice documents and other aids that help member companies fulfill their functional requirements. Member companies include names like Shell, BP, Dow and Akzo Nobel. NAMUR does not create standards, per se. Although many of its members also sit on standards committees outside of NAMUR, the purpose of the organization’s recommendation documents is to give the user some guidelines and best practices and to guide suppliers as they develop new products and applications.

Of particular concern to NAMUR is the role of the operator and maintenance technician and their impact on plant reliability and uptime. Unplanned downtime is one of the primary enemies of the process industries. According to ARC Advisory Group (www.arcweb.com), unplanned downtime accounts for the equivalent of 20% of all production in the process industries. A single unplanned shutdown can wipe out your plant profit for the year. In the same piece of ARC research, it states that 40% of unplanned downtime events can somehow be traced back to the operator or the human in the loop. We need not always blame the human in the loop, however, since that person may be working on faulty information or may not have the right information presented to them at the right time.

Today’s fieldbus device has unparalleled capability to diagnose its own state. NAMUR outlines 10 representative methods for self-diagnose field instrumentation, from signal processing tests to use of reference signals. The Foundation Fieldbus specification allows for many other methods of self-diagnosis of field instruments, including plugged impulse line detection and probe wear on electrochemical sensors.

Diagnostic data, however, is not of much use unless it is presented to those that need it in a timely fashion. It was in this same vein that NAMUR created a recommendation document called NE 107, "Self-Monitoring and Diagnosis of Field Devices," which outlines a series of recommendations on how to drive reliability and contextual presentation of fieldbus diagnostic data to the people who need it.

Figure 1. An operator needs to look at information from a wide array of systems, not just the distributed control system.

The operator and field diagnostics

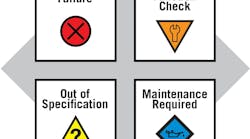

The role of the operator has become more complex (Figure 1). An operator needs to look at information from a wide array of systems, not just the distributed control system. Information comes from plant asset management systems, electrical reliability systems and other sources. There also are fewer personnel in many of today’s process plants, so the operator’s job has widened in terms of the scope of the plant. NE 107 categorizes internal diagnostics into four standard status signals — failure, function check, out of specification and maintenance required (Figure 2). Each of these categories can also contain greater detail. In the case of failure, for example, is the failure related to the device or the process? Is maintenance required immediately, or is the requirement more for long term maintenance?

Figure 2. The series of new field diagnostic alarms corresponds to the primary diagnostic categories outlined by NAMUR in its document.

Information overload or information in context?

Users also might become overwhelmed by the amount of diagnostic data that is possible from fieldbus devices. It requires some intelligent planning from both a work process perspective and a data management perspective. To address this, NE 107 also stipulates that the solution should be highly configurable, depending on the user’s requirements. Plant operators, for example, should only see the information they need to see. Anything that may cause an impending unplanned downtime event would be of interest to the plant operator. A device needing long-term maintenance would likely be of little interest. A bad diagnosis can be worse than no diagnosis at all, so NAMUR recommends that data should also be reliable, allowing the operator to take action at the right time. All the relevant diagnostic parameters should be clear and readable.

The information that the operator sees should follow the best practices and guidelines for alarm management. These best practices can be found in documents such as EEMUA 191, "Alarm Systems — A Guide to Design, Management and Procurement," from the Engineering Equipment & Materials Users' Association (www.eemua.org). True alarms should require immediate action, and care should be given not to overload the operator with too many alarms and alerts. This requires an audit of your current or planned alarms. The Abnormal Situation Management (ASM) Consortium (www.asmconsortium.net) also publishes several guidelines on alarm management best practices. The NE 107 recommendations don’t address this issue, but the implementation of standard status signals ensures there’s consistency in the presentation of diagnostic information and also ensures the diagnostic information is easily recognizable.

NE 107 also states the output of the status signal “must change immediately when the status changes” and the acknowledgement of the signal must never be required at the device level. This must be done by higher-level systems. Logging of status information in the device also is not a requirement.

Up-front planning for information flow

[pullquote]The Fieldbus Foundation strongly recommends that proper up-front planning be used to determine who needs access to information after the fieldbus system is up and running. While the NAMUR guidelines greatly improve how information is presented to the end user, be it the operator or maintenance technician, none of this is any good unless the person actually receives the information and then acts on it. Use of a plant asset management (PAM) system is essential for maintenance personnel to get the true advantages of fieldbus technology. Often, the use of a PAM system requires different work processes and a different philosophy from traditional reactive and preventive maintenance techniques that are prevalent in today’s process plants. The Fieldbus Foundation’s AG 181 System Engineering Guidelines offer several recommendations on the use of PAM systems, and the guide is available for free download at http://www.fieldbus.org/images/stories/enduserresources/technicalreferences/documents/systemengineeringguide.pdf.

Fieldbus Foundation incorporates NE 107 diagnostics

One of the advantages of Foundation Fieldbus is that it is a continuously evolving specification. It has the ability to incorporate and assimilate new technologies and requirements for process automation as they come along. After input from end users, this is what was done with the NE 107 recommendation. The Foundation was able to develop a profile specification based on NE 107 that could enhance the organization, integration and presentation of device diagnostics within fieldbus systems.

The diagnostic profile includes a standard and open interface for reporting all device alarm conditions and provides a means of categorizing alert conditions by severity. The technology facilitates routing of alerts to appropriate consoles based on user-selectable severity categories. In other words, it sends the right information to the right person at the right time without flooding the operator with alarms that are irrelevant to his duties. It also provides recommended corrective actions and detailed help, as well as an indication of the overall health of the device.

The Fieldbus Foundation accomplished the integration of the recommended diagnostic alert conventions— failure, function check, out of specification and maintenance required — by mapping the diagnostic information available from supplier Foundation Fieldbus devices through the device library portion of the fieldbus system. Now, any Foundation Fieldbus end user can take advantage of the diagnostics harmonization capabilities of NE 107 in the fieldbus system.

The ultimate result of this is a series of new field diagnostic alarms that correspond to the five primary diagnostic categories outlined by NAMUR in its document. Several additional supporting parameters are also available now, including enable/disable of diagnostic detection, configuration of priorities and configuration of alert suppression. With NAMUR NE 107 diagnostics built in, you can turn off diagnostics you don’t need or configure how the diagnostics are reported. This supports the configurability mandate of NE 107. Providing recommended actions and enabling simulation allows the information to be presented in greater context.

Testing, registration and interoperability

The Fieldbus Foundation also made it possible to register devices incorporating the new NE 107 recommendations. This ensures all devices comply with the specification and can provide interoperability with other devices and host systems. The Fieldbus Foundation updated its specification in August 2010 to incorporate NE 107, and it’s supported in Version 6.0 of the Interoperability Test Kit (ITK), allowing suppliers to test their own devices before submitting them for Fieldbus Foundation testing and registration. The Fieldbus Foundation registered the first Foundation fieldbus devices incorporating NE 107 recommendations in November 2010.

Support of field diagnostics is a mandatory feature in the ITK Version 6.0. The Fieldbus Foundation also is supporting NAMUR NE 107 at the host system level, and the latest version of the Host Test Kit (HTK) includes NE 107 diagnostics. Field diagnostics support is also mandatory in the latest 6b version of the HTK, and two hosts already have passed testing for this latest version.

What the Fieldbus Foundation brings to the table in terms of testing and registration at both the device level and the host level is a high degree of interoperability. The “Check Mark” is designed to ensure that devices from multiple suppliers will all work together and give full functionality of these devices at the host system level.

The Fieldbus Foundation continues to adapt to new technologies, recommendations and best practices. The new Foundation for Remote Operations Management technology provides integration of wireless field device networks.

Larry O’Brien is global marketing manager at Fieldbus Foundation (www.fieldbus.org) in Austin, Texas. Contact him at [email protected] and (512) 794-8890, ext. 16.