Blower packages get simplified test code

Blower manufacturers offer packaged centrifugal compressors and blowers in both a serial-production manner and made to order. The blower package is fitted with all of the necessary ancillary devices for operation and is marketed as a standard offering by manufacturers.

Existing test codes provide for detailed measurement of the core, or bare blower, but no test standard was available to measure a blower’s package performance; therefore, the Compressed Air and Gas Institute (CAGI) took on the task of developing supplementary codes referencing the existing flange to flange blower — compressor codes ISO 1217 and ISO 5389. The industry and the users of blowers needed a standard method of rating performance of the entire package. This provides users with relevant, accurate information regarding performance of the entire package, true wire-to-air performance.

The development of a standard for measuring package performance in the blower industry builds on work that was done with compressor standards many years ago. The result is a simplified test code for the many types of dynamic blowers along with a standardized performance reporting data sheet template.

| White paper: Understanding the CAGI BL 5389 standard This standard provides a simplified, wire-to-air performance test applicable to a packaged atmospheric air turbocompressor. |

CAGI BL 5389: Simplified Acceptance Test of Electric Driven, Low Pressure Turbocompressor Air Blower Package, is a standard that provides a simplified, wire-to-air performance test applicable to a packaged atmospheric air turbocompressor.

This code was developed as part of a broader standard that addresses all types of blowers and as an Annex (G) to ISO 5389, Turbocompressors — Performance test code, Second edition, 2005-12-15. The existing code was simplified to account for the lack of interstage cooling.

The turbocompressor package is defined as a blower with an electric motor drive: direct, geared, or gearless. The drive can be via a conventional electric motor, with or without an inverter, or by a high-speed motor with an inverter. The inverter can be integrated into the package or shipped loose.

Within the criteria of the existing packaged compressor test standard (ISO 5389, E.5.2.b) the definitions of limits to a moderate pressure ratio (≤ 3) and an adherence to Table E.1 for ideal gas behavior, the compression process of the package is considered isentropic — adiabatic and reversible. The compressibility factor (Z) of the air in this range is equal to 1.

To simplify calculations and the test procedure, corrections for Reynolds number and Mach number are considered negligible. This is accomplished by holding that predicted and measured impeller speed should be within 3%.

A standardized data sheet is developed for fixed speed and variable speed packages. The manufacturer provides the flow and specific power to achieve the stated flow at pressure increments of 2 psig.

The possibility for a Class A test (data sheet performance verification) and Class B test (client specified performance verification) is also provided.

BL5389 data sheet

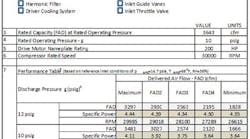

A sample data sheet for a standard packaged high-speed-turbo blower package reported delivered volume flow of the machine and the corresponding specific power for the stated operating speed (Figure 1).

Figure 1. A sample data sheet shows delivered volume flow of the machine and the corresponding specific power for the stated operating speed. CLICK TO ENLARGE THE IMAGE

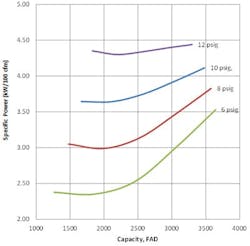

The information in the data sheet is can also be expressed as a chart (Figure 2).

Figure 2. The sample sheet data can be represented as a chart.

The stated performance is the volume flow and specific power at site conditions of 14.7 psia, 68 °F and 36% rh.

The test holds a positive 4% tolerance on work and volume. This means that the machine may produce 4% more air than predicted when it is tested. It follows that 4% more work would be needed to compress the air.

A ±4% tolerance on specific power is used. This is a practice followed in other industry test standards and allows for the normal variability of manufacturing.

Testing

Class A — Data sheet performance verification: The objective of testing is to confirm that the stated performance of a manufacturer’s standard package meets the published performance on each of the tabulated points.

The as-built package would be tested for volume flow (FAD) and power at the prevailing ambient conditions. For variable speed machines, measurements are taken at maximum, minimum, and three equally spaced speed points along the lines of constant pressure. The speed is noted for each of the operating points. For fixed speed packages, only the information for the maximum (nominal driven) speed is recorded.

Flow and power are measured and correlated back to FAD conditions. The package is then rated as pass/fail on each of the points. For a failure of any point, the data sheet verification is a fail.

Measurement inaccuracy is a part of any test. No measurement uncertainty tolerances are to be a part of this simplified test. All test data is to be considered absolutely accurate. All manufacturers participating in CAGI have the needed provisions to provide certifications of accuracy of instruments as part of his quality procedure.

Class B — Client specified performance verification: A Class B test was developed in response to a market need for testing of a custom or standard package to contract-specified guarantee points.

Following a Class A test methodology, a Class B uses the same methodology. The "as-tested performance data" is corrected to the contract-specified reference preconditions of a package inlet, rather than to the data sheet values.

This type of testing could be used if the site conditions are much higher (approximately 50 °F/28 °C) than the specified/guaranteed ambient inlet temperature. The machine may need to operate a significantly different speed in the field than at the test cell conditions.

The change in speed could depart enough to introduce some error in the predicted performance when corrected to site conditions. A means of correcting for this is taken with defined limits for a machine's Mach number.

This allows for testing of a custom package in a standard test cell instead of in an environmental test cell. The cost to perform a test in a standard test cell is much lower in this method.

Bottom line

The test procedures developed in CAGI BL 5389 provides uniform verification of the performance of the range of turbomachinery packages offered to the marketplace. The procedures are robust and accurate. Standardized data sheets for commercially offered packages are being prepared by the members of CAGI. These will be published in fall of 2014. The third-party independent verification program now being used for compressor packages is being discussed for blower packages, as well.