Boilers are often the principal steam or hot-water generators in industrial plants. Consequently, they must be designed to operate efficiently and safely while responding rapidly to demand changes. Burner-management systems must be equally adaptive. Control techniques are capable of reducing operating costs while providing greater flexibility in plant management and control. Tools for burner combustion control generally include regulation of excess air, oxygen trim, burner modulation, air/fuel cross-limiting and total heal control. The better burner control systems include all of these elements.

Excess-air regulation

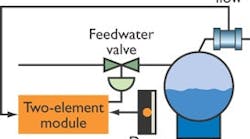

In practice, gas-, oil- and coal-burning boilers don't mix fuel and air perfectly, even under the best conditions. Figure 1 shows that keeping excess air within a specific range ensures complete combustion and reduces heat loss. Effective regulation of excess air:

Improves heat-transfer rates.

Provides advance warning of flue-gas problems.

Offers substantial fuel savings.

Oxygen trim

Knowing the oxygen concentration in the flue gas improves combustion control. Adding an oxygen trim-control module allows:

Tighter control of excess air.

Faster return to setpoint following disturbances.

Tighter emission control.

Easier carbon monoxide or opacity override.

Optimize excess air

Figure 1:

Excess air must be kept within a suitable range to ensure complete combustion and reduce heat loss.

Air before fuel

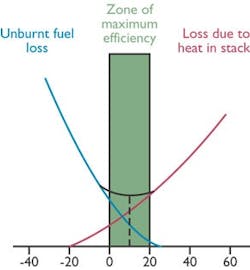

Figure 2:

A cross-limiting combustion circuit allows firing multiple fuels simultaneously without risking excess fuel.

Burner modulation

Modulating control improves boiler operation by monitoring the steam or hot-water line to produce a continuous control signal that determines the fuel input. Reductions in steam pressure or water temperature lead to an increase in firing rate. The advantages of burner modulation for combustion control include:

Continuously matching fuel and air rates to demand.

Closer steam pressure or water temperature tolerances.

Improving boiler efficiency.

Reducing the weighted average flue-gas temperature.

Air/fuel cross-limiting

A cross-limiting combustion-control strategy ensures there can never be a dangerous air/fuel ratio in the system. This feature always increases the airflow before increasing the fuel flow and always reduces the fuel flow before allowing the airflow to drop. Figure 2 illustrates the concept. The scheme easily accommodates firing multiple fuels simultaneously. Cross-limiting combustion control is highly effective and can:

Optimize fuel consumption.

Reduce the risk of explosion.

Adapt to variations in fuel and air supplies rapidly.

Better satisfy steam demand.

Applying additional dynamic limits to air and fuel setpoints can achieve additional savings by maintaining the air/fuel ratio within narrow limits during and after transition. This reduces heat loss by protecting against the demand signal making the air/

fuel ratio too lean.

Boiler drum-level control

Boiler drum-level control is critical. Too low a level may expose boiler tubes, which overheats and damages them. Too high a level may interfere with separating moisture from steam, which reduces boiler efficiency and carries moisture into the process or turbine. The drum-level controller maintains the level at constant steam load. There are three options for drum-level control single-element, two-element and three-element drum-level control.

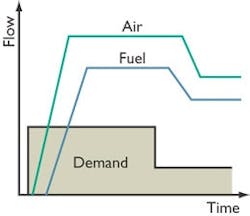

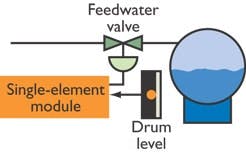

Single-element control is the simplest but least effective form of control (see Figure 3). A proportional signal or process variable (PV) signal generates a correction that's proportional to the deviation from setpoint. The output controls the boiler's feedwater valve. Single-element control requires one analog input and one analog output. Because there's no relationship between drum level and steam or feedwater flow, it can be applied only to a single feed pump on a single boiler supplying a relatively stable load. Also, the swell effect may render control inadequate.

Easiest way

Figure 3:

Drum-level control with a single-element module.

Typical

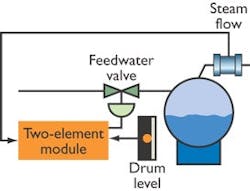

Figure 4:

Drum-level control with a two-element module.

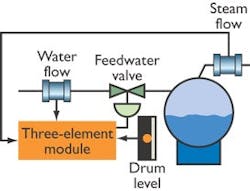

Best way

Figure 5:

Drum-level control with a three-element module.

Two-element drum-level control can best be applied to a single drum boiler if the feedwater is at a constant pressure. Two-element control (see Figure 4) includes the same level element used for the single-element configuration but has an added steam-flow element that provides a density-corrected mass flow-rate signal to control the feedwater flow. Two elements offer tighter control of drum level. The steam flow acts as a feed-forward signal to allow faster level adjustments. This gives an immediate feedwater response to load changes while the level controller corrects any imbalance between steam mass flow and feedwater flow that arises from:

Blowdown variations caused by changes in dissolved solids.

Variation in feedwater supply pressure.

Steam leaks in the steam circuit.

Three-element drum-level control is suited for handling variable feedwater pressure or multiple boilers with multiple feedwater pumps (see Figure 5). The three elements in this system handle level, steam and feedwater flow. The level and steam elements correct for unmeasured disturbances arising from boiler blowdown, as well as leaks in the boiler and superheater tubes. The feedwater flow element responds rapidly to variations in feedwater demand that arise from the steam flow-rate feed-forward signal and feedwater pressure or flow fluctuations.

To achieve optimum control, both steam and feedwater flow values should be corrected for

density. This provides tighter drum-level control. It's appropriate if a system suffers from fluctuating feedwater pressure or flow, or if a more sophisticated control is required.

To stabilize control over a wide range of steam demand, the three-element mode acts during high steam demand, but can drop back to two-element mode if the steam-flow measurement fails. The module reverts to single-element level control if the feedwater flow measurement fails or if steam demand is low.

Demand-load scheduling

A primary goal in operating a boiler plant is ensuring the working steam pressure (or temperature in a hot-water system) is constant for any load demand placed on the plant. Some valuable features of demand-load scheduling include base load or modulating operation, parallel or serial demand sharing, boiler banking and programmable sequence selection.

In a multi-boiler plant, demand-load management optimizes the distribution of steam demand among the units and adjusts the overall output to meet working requirements. This ensures that boilers are fired only when required, thus reducing operating costs. Alternatively, demand-load management can allow each boiler to operate for the same amount of time.

A demand share arrangement should allow each boiler to operate in either base-load or modulating service to achieve the best distribution of load. In base load operation, the total demand is shared among the base-loaded boilers in accordance with user input. The modulating mode of operation, on the other hand, automatically enforces the load allocation without operator intervention. The total demand, less that satisfied by the base-loaded boilers, is shared among the modulating boilers in proportion to their capacities. Effective load allocation is based on real-time calculations that account for operating safety margins, load fluctuations, shutdown characteristics and boiler capacities.

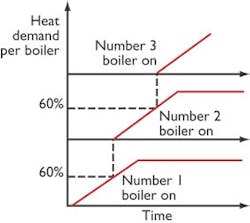

Chained heat

Figure 6:

With series demand sharing, the modulating boiler's firing rate increases until the load requires an additional boiler. Then the additional boiler starts and becomes the modulating boiler.

Demand sharing also can be implemented in parallel or series. In parallel, the boilers share the total demand using equal firing rates. On load increase, the firing rate of each increases equally until the load requires an additional boiler. Then, the firing rate of the active boilers decreases to compensate for the firing rate of the additional boiler.

Steam boilers generally use parallel modulation. It offers the most effective control for relatively steady process loads. The controller provides a smoother response to changing loads by modulating the boiler plant to maintain header pressure.

Series demand-sharing allocates loads by modulating one boiler at a time to satisfy demand (see Figure 6). On load increase, the modulating boiler's firing rate increases until the load requires an additional boiler. Then, a new boiler starts and becomes the modulating boiler. The other boilers have already been ramped to their optimum firing rate. Series modulation is generally implemented for hot-water systems or fluctuating steam loads. It allows faster individual boiler response to plant conditions as the boiler pressure is adjusted to the required setpoint.

The boilers that always operate are referred to as lead boilers, while the others are called lag boilers. The most effective boiler always starts first and the least effective always stops first.

Boiler banking keeps boilers in hot standby mode by intermittently firing unused boilers, thus maintaining a required pressure. Boiler banking acts as a warm-start facility, improving the plant's response to sudden load changes.

Remember that demand-load management is an optimizing function that augments, but doesn't replace, the combustion-control system.

Taken together, burner modulation, air/fuel cross-limiting, excess air regulation, oxygen trim and total heat control can provide excellent control and fuel efficiency for most boiler systems.

Rob Kambach is senior technical specialist at Invensys Foxboro in Foxboro, Mass. Contact him at (508) 543-8750.

Figures: Invensys Foxboro