Several reliability measures and calculations are available. Two of the most useful are overall equipment effectiveness (OEE) and total effective equipment performance (TEEP). They are calculated as follows:

|

View more asset management content on PlantServices.com |

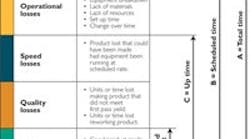

OEE = good product/(operational losses+speed losses+quality losses).

TEEP = good product/(operational losses+speed losses+quality losses+planned losses).

OEE and TEEP can be calculated easily and applied to critical manufacturing equipment. These measures determine the reliability levels of equipment and systems.

Measuring and charting OEE and TEEP presents a clear picture of where losses are located (Figure 1). This helps determine the most economically worthwhile areas to apply reliability-centered maintenance (RCM) and root cause analysis (RCA).

Reliability-centered maintenance

The RCM process

RCM analysis is a structured process that requires experience and discipline to complete. It has three stages:- Preparation work.

- Analysis.

- Implementation.

Prep work

Preparation involves selecting a process, forming and training the analysis team and gathering critical information. It also requires a document that outlines the following:

- Names of RCM analysis team members.

- Analysis meeting schedule and location.

- Expected outputs from the RCM analysis.

- Drawings, existing procedures, and equipment and system histories.

- A written operational history report that states clearly the design intent of the process and its present operating conditions.

- The implementation manager for analysis tasks.

- An implementation meeting schedule.

- Signatures of the RCM team, facilitator, operations and maintenance managers.

Completing this document helps guarantees a successful analysis. It communicates the objective, resources and time required to complete the process.

Overall equipment effectiveness (OEE). Total effective equipment performance (TEEP)

Analysis

The analysis stage also requires structure and discipline. It's best completed by using the blitz format.

The team follows nine steps to develop a maintenance strategy for the process or piece of equipment being analyzed.

- List process functions.

- List functional failures.

- List failure modes.

- List the probability each failure will occur.

- List the effects of failure.

- List the consequences of failure.

- Run the failure mode through a RCM decision process.

- Develop a maintenance task, redesign or consequence reduction task.

- Run failed part through a RCM spare parts decision process.

In performing this step of the process (also known as a modified failure mode and effects analysis), the RCM facilitator notes the components the team has designated as having a high probability of failure and assigned a medium to high consequence rating. These components are prime candidates for root cause analysis (RCA). RCA focuses the team on the various causes of component failure, including physical, human and latent.

Once these nine steps are completed, the team can develop a maintenance strategy for the process (equipment) being analyzed. It includes maintenance tasks such as:

- On-condition maintenance tasks (vibration analysis, thermographic analysis, motor current analysis, process verification, etc.).

- Preventive maintenance tasks (scheduled rework, scheduled discard, scheduled inspections).

- Failure-finding tasks.

- Recommended redesigns.

- Consequence reduction tasks (for components where run-to-failure is the maintenance strategy).

The procedures that accompany these tasks must be written clearly with specific content. They must state what should be observed, measured and recorded, as well as what to do if an undesired condition exists.

Implementation

Once the analysis is completed and reviewed, the team establishes an implementation strategy.

If this stage is not completed, the team has wasted time and money. It consists of four steps:

- Prioritizing the tasks based on probability and consequence.

- Assigning a specific person to implement the task.

- Assigning a due date for the task implementation.

- Tracking and reporting implementation progress.

Once the implementation is completed, you can expect to see results such as these:

- Improved OEE and TEEP.

- Reduced maintenance costs.

- Reduced unit production cost.

- Fewer health, safety and environmental incidents.

- Improved quality.

- Reduced emergency maintenance.

- Reduced spare part inventories.

- Reduced set-up times.

- Reduced turnaround time.

- Reduced speed losses.

A completed and implemented analysis can save millions of dollars easily. The key is to use to OEE and TEEP to identify the processes that merit RCM and RCA.

Douglass J. Plucknette is president of Reliability Solutions, a firm specializing in manufacturing and equipment reliability consulting. He can be reached at (585) 349-7245 or at [email protected].

Robert Latino is senior vice president of strategic planning for Reliability Center, Inc., a 17-year-old firm specializing in helping businesses, industry and government organizations improve reliability. He can be reached at (804) 458-0645 or at [email protected].