Preventing catastrophic failure from a dust explosion

Robert Comer’s book Explosion Vented Equipment System Protection Guide provides practical applications and guidance to analyze and design or retrofit dust collection equipment to prevent dust explosions. According to Comer’s book and the U.S. Chemical Safety Board, 316 dust explosions have occurred over the last 30 years, killing 145 workers and injuring 846, not to mention causing extensive damage to facilities. He also says more than 130,000 plants worldwide handle sugar, flour, starch, dried milk, egg whites, gluten, and artificial sweeteners, which can produce combustible dusts and potential explosions. “Milling, grinding, spray drying of liquids, and handling of grains are processes that generate combustible dust. Combustible dusts are common in the food, plastics, metals, agriculture, chemical, and wood industries,” Comer says.

Looking for other great content to read? Reliable Reading will review stellar books on the maintenance and reliability industry, leadership and management practices, and anything that relates to professionals in our industry.

The National Fire Protection Association (NFPA) also released a new standard 652, “Standard on the Fundamentals of Combustible Dust.” It applies to all agricultural and food production facilities, which are required to complete a dust hazard analysis (DHA) by September 2020.

Comer’s book provides design criteria and guidance for the safe venting of dust collection systems. The book is intended to be used by engineers that understand the concepts and use them to determine the required reinforcing design when reviewing equipment supplied by manufacturers, and manufacturers can use it to design their equipment to meet a certain pressure threshold for a user.

The book is organized in two parts. Part one provides the structural analysis and design for reinforcing dust handling equipment and explosion relief ducting. Part two provides the analysis of dust handling equipment for determining the explosion relief flowing pressure (Pred), based on the process dust explosion characteristics and structure of the equipment. “If equipment has been designed to be explosion vented and has an explosion vent built-in or proposed, there must have been an explosion venting analysis performed specific for the process dust being handled and geometry of the system,” Comer says. If the analysis shows that the equipment provides the needed Pred, then part one of the book can ensure the integrity of the system. If the equipment manufacturer does not provide the needed analysis, part two will provide the guidance to size the explosion relief burst element ducting, and to calculate the Pred.

The book outlines the needed mathematics and design elements that engineers need for a safe system. Here, I will outline some of the major elements of those systems and important considerations when reviewing a current system or building anew.

Dust collector and venting duct design are not standard

How much better would we all clean if the dust in our homes could cause an explosion? I know I might dust a little more often (though you’ll learn later that’s not a good cleaning technique for the plant floor.) In industrial processes, dealing with dust is serious business, as the statistics about death and injury confirm.

How authentic leadership can help drive business results

A good leader is an organized leader

How to utilize checklists to improve your maintenance program

While we can discuss a typical dust collection system, it’s important to note that each individual system must be matched to the process product and production operation. Dust collectors are typically square/rectangular or round/cylindrical. The system itself generally needs reinforcement in order to withstand the power of an explosion should one happen to vent the danger away from people and equipment. This includes the dust collector walls, roofs, hopper sections, access doors, nozzles, and supports. Comer says a cylindrical vent duct rarely requires reinforcing, while a square or rectangular one almost always requires it.

In the case of an explosion, vent ducts protect lives and equipment

Systems can also be interior or exterior, depending on the design. An interior dust collector should have an explosion vent duct to the outside through an exterior wall or up through the roof. The author did note an alternative to the explosion relief ductwork is the use of a flameless vent, installed over the standard vent to extinguish the flame in the vented area. “These devices allow the venting to be inside without a duct to the outside when access to the outside is remote or venting to a safe location is not possible,” Comer says.

Exterior dust collectors need a vent duct or blast defector if the area allows personnel access. “In all cases, attention must be given to any access doors, ladders, or air intakes to other equipment in the area and ensure that the fireball avoids them,” Comer says.

General housekeeping is as important as system design

Even with a dust collection system hazardous dust can accumulate on surfaces, and it’s important to clean regularly. “The standard allowable duct layer accumulation is 1/32 in. on at least 5% of the floor area,” Comer says. The floor area calculation includes beams, ducts, equipment, and any vertical surface where dust can stick.

It’s also important to clean with the proper equipment. Put away those dusters. Vacuuming is the preferred method, and industrial vacuum cleaners must be approved for use in Class 11, Division 2 areas. Compressed air blowing is forbidden, as it could form an explosive dust cloud. Brushing or broom cleaning is also a no-no, as it likely spreads dust to other surfaces.

Know your process dust characteristics

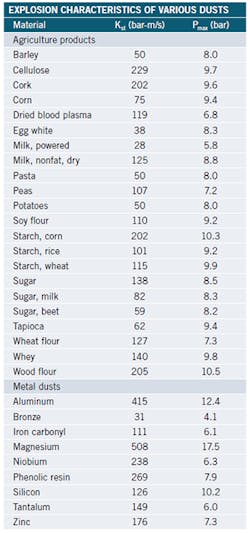

All process dust should be tested in accordance with ASTM Standard E1226, “Standard Test Method for Pressure and Rate of Pressure Rise for Combustible Dusts.” The explosive behavior of dusts is described in terms of the maximum explosion pressure and the rate of pressure rise. “Kst is the normalized rate of pressure rise of explosion pressure and is the average of the largest observed rates from each series of tests. Pmax is the average of the largest explosion pressures observed from each of three test series,” Comer says.

The list on this page compiles dust characteristics for agricultural products and metal dusts, compiled from various sources, primarily from NFPA standard 68. “The value listed may not be the same as your dust characteristics,” Comer says. The characteristics and explosive behavior of dust is the foundation for what type of system is needed to make the process safe. Each process dust should be tested, and if products or processes change, those tests need to be redone. Know your dust, so you know how to vent it properly.

This story originally appeared in the June 2022 issue of Plant Services. Subscribe to Plant Services here.