Thiago Figueiredo, vice president of aftermarket for Quincy Compressor, has been in the compressed air industry for over 13 years developing new service products, sales and marketing strategies, and managing sales and operations. During the live Q&A portion of the webinar, "Compressed Air as a Utility: How This Market Trend Will Affect You and Your Operations," Figueiredo tackled several attendee questions on capital investments and the benefits of compressed air as a service.

PS: You mentioned something profound about the capital expense approval process: "Things take longer to get approved, and this can lead to emergencies, especially when the new equipment can't arrive on time." What are you hearing from the industry? Did finance teams alert you to this trend where suddenly the approval process is so onerous that it's actually introducing risk rather than mitigating risk?

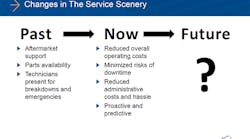

TF: In general, purchasing processes are moving from the hands of individuals to procurement departments. This is quite common in medium- to large-size companies. This means that one individual has less ability to make a decision for a purchase, and when the purchase goes through, (there is) more scrutiny. When we talk to maintenance managers or facilities managers, we learn that the hassle increases when purchasing gets involved, so that lengthens the process.

When we're talking about equipment that is vital to a customer's production, we might end up having a delay of six weeks to three months to get a purchase order (PO) issued to a supplier to come in and do maintenance. This delay can cause maintenance to go from preventive to red-hot emergency, increasing the risk of a breakdown. Customers that follow this process every time maintenance is needed often end up suffering additional days of downtime.

PS: You mentioned that new conversations are taking place between maintenance, reliability, and operations teams as purchasing evolves, in some cases, towards the services model. What new conversations will these teams be expected to have now that they weren't having two or three years ago when it comes to services?

TF: Companies often postpone capital purchases as much as possible because those purchases can have very long-term consequences. If we buy a new piece of equipment, we have to live with it for 5 to 10 years, depending on how a company's finances work and the length of depreciation for that equipment.

When it comes time to do a major overhaul on a piece of equipment, like an air compressor, often companies choose to overhaul the equipment because of the much shorter timeframe. If they buy a new piece of equipment, then that’s another 10-year commitment, so instead they choose to overhaul the equipment.

Sometimes technology is changing so dramatically and there is so much more efficiency to be gained from a new piece of equipment that buying new equipment might be the better option. But then again, ask yourself, do I want to have that commitment? The conversations that are being had are around balancing that risk. But now the tone of the conversation changes because I'm no longer having to have that balance. I can choose to replace that piece of equipment and benefit from having additional reliability and higher energy efficiency without having the large capital investment.

PS: Last year, one of our contributors wrote on the hidden costs of compressed air reliability in the form of rental units. He's been in situations where those rental units simply begin adding up in the yard whether they are being used or not, and he found that to be one of the low-hanging fruit that could be looked at by energy managers or reliability engineers when managing compressed air cost. As you're saying, when you don't have the responsibility for the capital costs, those hidden costs also vanish for extra rentals that may or may not even be used.

TF: Absolutely. A lot of customers are deciding not to have redundancy. They're deciding to operate with the machinery that they can afford or the amount of capital that they are willing to disperse, and they end up having to have rental units on site for major services or repairs, and that has a very high cost. I think the proposition of looking at air as a service, where “If I use more of it, I pay more for it, if I use less of it, I pay less for it,” is way more attractive because it aligns with companies' requirements.

PS: If you have several companies offering these services, what are some of the standout KPIs that a customer should look for in order to select the best choice?

TF: If I'm looking at it from the perspective of a customer, then I would be primarily thinking about risk and the level of commitment. How much risk do I have in my business moving forward, and how much am I willing to commit? What if something changes drastically and I no longer need that equipment? From a more positive perspective, what if something changes drastically and I need more equipment or I need more of that equipment? Do I have the ability to modify what I have today and not have high costs associated with it?

That's ultimately what I'm trying to avoid. That would be one of my key factors when considering machine as a service. As I mentioned, it's not something new, we're not reinventing the wheel, but the different options in the market offer different flexibility levels as well.