In brief:

- Half of the compressed air produced in industrial systems is typically wasted through leakage, artificial demand and inappropriate use. An audit can identify this waste. Eliminating the waste can reduce the number of compressors required, freeing the existing unused compressors to provide backup.

- When storage receiver capacity is too small, compressors will cycle too frequently, which shortens air end life. A small change in system demand will cause a rapid change in pressure, which will cause the compressors to overreact.

- Properly sized system storage helps protect against the failure of the largest compressor, which means a backup compressor with adequate capacity must be available and capable of automatically starting, and sufficient storage capacity is needed to slow the rate of pressure loss while the spare compressor starts..

- An automation system can manage compressors within a single control band by cycling only one compressor at a time. By monitoring the rate of pressure change, the automation system can respond to air demand changes without unnecessary cycling or compressors starts.

All rotating equipment will eventually fail, and the compressors that supply your compressed air systems are no different. Ignoring this fact may mean trouble for your plant production, or worse, cause a complete production outage. In a well-designed system automatic backup strategies to recover from this failure will be in place and, if implemented correctly, should cause minimal pressure fluctuations or compressed air system performance degradation.

Unfortunately, in today’s world of restricted capital availability, justifying backup equipment can be very difficult, especially in the case of facility support equipment. But without backup equipment, especially air compressors, the ability to maintain preventive maintenance schedules can be impacted, relegating maintenance of critical facilities equipment to off times like evenings or weekends, or not at all, so overall reliability is negatively impacted. Without adequate maintenance, the potential for a failure in the system increases exponentially.

Figure 1. Half of the compressed air that’s produced is wasted in the form of leaks, inappropriate uses and artificial demand. (Source: Compressed Air Challenge)

For firms specializing in industrial compressed air and vacuum audits, the most common marching orders from clients are to find energy savings and do something to increase systems reliability. Fortunately, these two basic needs work together in compressed air and vacuum systems. As identified by the Compressed Air Challenge, 50% of the compressed air produced in most industrial systems is typically wasted through leakage, artificial demand and inappropriate usage (Figure 1). This means, if sufficient waste can be found and eliminated from a system, one or more compressors can be turned off creating energy savings and providing a backup unit.

There are a few basic maintenance and operational practices that must be managed or maintained to improve compressed air reliability.

- Improving compressor room ambient air ventilation to reduce compressor inlet temperatures will reduce internal and discharge temperatures, which are the source of many unexpected shutdowns. If your compressor room is more than 10 ºF above ambient, then some additional ventilation should be considered. If the compressors are air-cooled, duct the heat outdoors in summer to reduce temperatures and indoors in winter to recover heat. This heat recovery can provide enough energy savings to fund the project.

- Dirty or fouled inlet filtration on air compressors causes a compressor to work significantly harder to deliver the same volume of air. The fouled filter creates a vacuum at the compression element, but the discharge pressure requirements stay the same, so this is an increase in the required compression ratio on the compressor. This vacuum at the inlet also means the compressor must increase its output capability if it can, by increased speed, modulation level or loading percentage, in order to deliver the same volume as it could with clean filters. This is an energy issue, as well as a maintenance issue, as it causes the efficiency to fall and the temperatures to increase.

- Internal pressure drop across fouled compressor heat exchangers and separators also forces the compressors to work harder to deliver the same air flow. This will result in higher amp levels on the motor and higher temperatures. Filter and dryer pressure drop after the compressor discharge has the same effect and should also be monitored and managed at minimum levels. Find out what the specifications are for pressure drop on this equipment and then monitor it with an accurate gauge to determine when flushing or element replacement is required.

- In the case of heat exchangers, the fouled cooler that creates pressure drop also leads to higher temperatures because the ability to remove heat is impacted. Monitoring approach temperatures is often the best way to monitor for these kinds of problems. Again, get the specifications from the manufacturer and compare the outlet air temperature to the inlet cooling medium temperature with an infrared temperature gun to quickly learn when maintenance is required.

- Monitoring and managing leak levels can create the opportunity for a backup compressor and reduce system pressure, but, at a minimum, it will save energy. Performing a leak audit with an ultrasonic gun on a priority basis — larger leaks first — will maximize results and minimize costs.

- Failed condensate drains are the leading cause of air system contamination. Testing drains every day as part of a normal operator walk-through is recommended and offers the opportunity to catch these problems before they affect production. There are no maintenance free drains and even the best technology available requires regular rebuilding to be reliable.

The systemic overview

The missing ingredient in virtually every compressed air system is sufficient storage receiver capacity, but how does this impact reliability? When storage values are too low, relative to compressor size, the compressors will cycle too frequently, which shortens air end life. Additionally, a relatively small change in system air demand will cause a rapid change in pressure, which will cause the compressors to overreact trying to maintain the system setpoint. To compensate for these fluctuations, the average system pressure level is often increased to ensure the pressure stays above the minimum acceptable level for production. This increase in pressure creates artificial air demand, one of the primary waste categories, where the higher pressure causes unregulated uses and leakage to consume more air than at lower pressure, but it also increases the work the compressors must perform to provide the required compressed air. Even if the compressors are rated for the actual operating pressure, every 2 psi increase in discharge pressure increases the work energy required by 1% (at a nominal 100 psig) increasing compressor component operating temperatures, decreasing the lifespan and increasing required maintenance costs. In worst case scenarios with minimum storage capacity, backup compressors will be left running unloaded, so they can quickly be available to maintain stable system pressure with the obvious negative impacts on operating and maintenance costs, and unit life.

In addition to unstable system pressure, there are other reasons for a higher-than-necessary operating pressure, including excessive pressure drop at the point-of-use filters and regulators, insufficient storage at the point of use for high-speed applications, unregulated open blowing and elevated leak rates, which pull down pressure locally and affect other applications. Any steps to reduce operating pressures are going to have a positive impact on reliability, long-term equipment integrity and operating costs, so identifying these types of issues is critical. One option would be a complete professional system audit, which would address all of these areas in order to minimize system pressures.

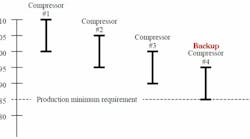

Properly sizing system storage is primary to minimizing these issues and starts with providing for the failure of the largest compressor without having the system pressure fall below the minimum acceptable level at any time. This requires two considerations. First, a backup compressor with adequate capacity must be available and capable of automatically starting. Second, sufficient storage capacity is needed to slow the rate of pressure loss so that the compressor can load up before system pressure drops too low. The size of storage required is dependent upon the size of the largest compressor and can be surprising (Figure 2).

Figure 2: A cascaded control scheme results in higher average system pressure but allows automatic backup to function.

If this setup is applied on a system with four 200-hp 1,000-cfm-rated compressors in a system that has 1,100 gal (10 cubic ft/psi) of storage capacity, the failure of a fully loaded compressor would cause the pressure to fall at a rate of 100 psi/min (1.67 psi/sec). If the spare compressor takes 20 seconds to start and load, system pressure will have fallen about 33 psi before the spare unit delivers any air. If, on the other hand, the system had 10,000 gal of storage capacity, the pressure would have only fallen 3 psi for the same event. With this cascaded control strategy, system pressure will range as high as 110 psi and as low as 90 psi through the normal operating range of the control scheme, which is not preferable but can be managed in several ways, such as a pressure flow controller or an automation system.

Figure 3: By monitoring the rate of pressure change, the automation system can make decisions to properly respond to air demand changes without unnecessary cycling or compressors starts.

Properly designed automation systems can manage a set of compressors within a single control band by cycling only one compressor, while any other units which are operating remain fully loaded (Figure 3). Additionally, by monitoring the rate of pressure change, the automation system can make decisions to properly respond to air demand changes without unnecessary cycling or compressors starts. Combined with a pressure flow controller to stabilize system pressure, automation can maximize efficiency and reliability by monitoring compressor operating conditions and alerting operators when appropriate. Modern automation can even shift compressors with abnormal conditions to the back of the sequence and start other units in their place.

[pullquote]Annual preventive programs should be scheduled for compressors prior to the worst conditions occurring. Normally, the worst conditions are in the summer, so spring time is the best time to clean coolers, replace filter elements and perform any other preventive activity. Going into the summer’s higher temperatures with the compressed air equipment in its best possible condition will minimize the risks of an interruption and maximize the reliability of the compressed air system.

Dean Smith is a certified Compressed Air Challenge Level II instructor and qualified to lead CAC’s LI and LII seminars. He is general manager of iZ Systems. Contact him at [email protected] or (404) 307-6836. Alton Stokes is senior air systems auditor at iZ Systems. Contact him at [email protected] or (251) 490-4981. For more information, visit www.compressedairchallenge.org.