It used to be so easy. Large plants with a maintenance staff of hundreds expected to spend big bucks on a computerized maintenance management system (CMMS). Small plants with fewer than 30 in maintenance could rarely justify spending much, if anything, on the software. And hundreds of vendors were vying for the plants in between. Then along came client-server technology, the Web and improved software functionality and lower prices. Now, smaller shops can more easily cost-justify a CMMS, and large shops are encouraged to move on to their second, third and even fourth CMMS.

In today's confusing marketplace, understanding key differences between the requirements of small and large maintenance shops within single or multi-plant environments facilitates purchasing the right CMMS.

|

View more asset management content on PlantServices.com |

Scalability

A typical small plant can sustain a higher percentage of growth than a large plant, although the increase in absolute dollar revenue or number of employees is small. For example, a $10-million business can double in size in one year, whereas a $1-billion business is less likely to do so. However, a mere one-percent increase in the $1 billion business is equivalent to the doubling of the $10 million business in terms of absolute dollar revenue growth.

Small companies must, therefore, purchase a CMMS while keeping an eye on possible expansion by one or more orders of magnitude during the following few years. It's managing this level of change that's exciting, but taxing on a small company. Proper asset care is a critical success factor for a rapidly growing business because the company must maximize capacity during its growth spurts.

Large, multi-plant enterprises seeking to standardize on a CMMS have an interesting dilemma. Some plants in the conglomerate may be quite large, but some may be small. The standard CMMS package must be scalable to accommodate both sizes, which may not be possible economically. Some CMMS vendors offer so-called lite versions, which have scaled down functionality for the smaller plants. This allows migration to the full-function versions if the plant's size or needs grow. Information also can be standardized, shared and even centralized across the corporation. Unfortunately, some of the smaller plants find these scaled-down versions less desirable in terms of price and functionality than packages designed specifically for their market segment.

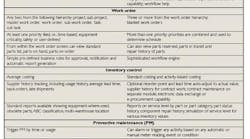

Core features and functions

Contrary to popular wisdom, small maintenance operations are just as keen to purchase high-quality software as are large maintenance shops. Attributes, such as fast response time, high reliability, ease of navigation and consistent screen design, are just as critical for a small plant as they are for a large one. It's the quantity and complexity of functionsnot qualitythat varies across the company size spectrum.

Regardless of the size of your company, expect certain core features and functions no matter what the cost or market focus of the CMMS package. Generally, as company size increases, in certain niche markets and in light of specific business requirements, the demand for more advanced functionality increases.

Integration

A consideration for small businesses is the package's level of integration. Because resources are thin, it's desirable to limit variation in software and hardware. A small manufacturer that can find fully-integrated accounting, sales, manufacturing and CMMS software from a single vendor will save on training and support costs. The downside is that the package may not be best-of-breed. For example, the accounting modules may be superb, the manufacturing modules satisfactory and the maintenance modules clearly a compromise.

Price

The key question for small companies has always been one of getting the needed features and functions at a reasonable price. It's surprising just how much functionality one gets in a CMMS for under $1,000. Some CMMS vendors sell individual modules, such as preventive maintenance, for even less.

A typical small company looks for off-the-shelf software that can be implemented without direct vendor support. Implementation support includes installation, setup, data entry and conversion, training and customization. The CMMS vendor also wants to minimize the need for direct support, because it can't afford to sell huge volumes of low-priced, shrink-wrapped software and support each customer fully. However, experience shows that to be successful, many smaller companies eventually seek implementation and support services from local distributors and consultants.

Contributing Editor David Berger can be reached at [email protected].