- Intern approaches pump alignment with laser accuracy.

- Tips to compare the energy wasted by a hot coupling to the energy loss.

- Misalignment affects bearing load and excessive bearing load causes exponential decreases in bearing life.

In the summer of 1994, Jack Lambley, an intern at Imperial Chemical Industries’ (ICI) Rocksavage site in the United Kingdom, was quantifying the effect of misaligned process pumps on power consumption. He arranged to have a surplus pump overhauled and fitted with new bearings. He then had the pump installed in a suitably instrumented closed-loop arrangement operating on water. Prüftechnik loaned Lambley a laser-optic alignment instrument.

As an undergraduate student, Lambley had learned that misalignment affects bearing load and that excessive bearing load causes exponential decreases in bearing life. His supervisor, Steve Moore, had asked Lambley to read the engineering sections of SKF’s general catalog, which stated that a 25% increase in bearing load cut its rated life in half.

Lambley investigated alignment accuracy and methods the plant was using at the time. He found that straightedge methods were inappropriate for refinery pumps. Rim-and-face alignment methods were judged to be difficult and generally unreliable. Properly executed, reverse-dial-indicator methods required consideration of bracket sag, which would take more time. Still, from data available at Rocksavage, he calculated that typical misalignment was 0.02-in. vertical and horizontal offsets and 0.002 in./in. vertical and horizontal angularity.

[pullquote]In 1994, lasers were already known to be inherently more accurate than the best competing techniques. Lambley believed them to be 10 times more accurate.

The graphs and tabulations Lambley constructed are reproduced here, duly acknowledging ICI’s role. The recommendations coming out of the study suggested aligning machinery to within 0.005-in. shaft offset and limiting deviations in hub gap to 0.0005 in./in. of hub diameter. Lambley further documented that adhering to these recommendations could reduce ICI’s power consumption by about 1%. He confirmed that laser alignment was fast and accurate. He found that laser-alignment technology was bottom-line cost-effective. He deserves credit for establishing facts instead of repeating the opinions of others.

The following data is from a typical mid-sized refinery:

Average annual electrical demand for pump motors:

27 kW/pump x 8,760 hrs/yr x $0.10/kWh x 1,000 pumps = $23,652,000/yr

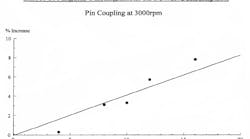

Figure 1. Effect of parallel offset on power consumption of a pin coupling at 3,000 rpm.

The ability to save 1% of this total represents a gross annual savings of $236,520. It ignores the cost of laser alignment instruments and appropriate training. Also, it’s reasonable to assume 7 labor-hours of time-saving credit per alignment job. Alignment work usually involves two craftspeople and a few hours of operators' and supervisor's time. Including the overhead contributions of operating and supervisory personnel, the total job typically consumes 15 man-hours with dial indicator methods and brackets, for which one needs to determine and take into account bracket sag. In contrast, it is reasonable to assume that laser-alignment by a two-person crew, including the inevitable participation of supervisory and operating personnel, takes perhaps eight man-hours. That would explain the seven-hour savings, which could also be expressed as a roughly 40% reduction in total man-hours for laser-alignment tasks.

Figure 2. Effect of angular misalignment on power consumption of a pin coupling at 3,000 rpm.

For even more information, learn about thermography and infrared monitoring techniques. These technologies quantify beyond any doubt the temperature increase in a coupling located between misaligned pump and driver shafts. You might compare the energy wasted by a hot coupling to the energy loss Lambley described. You’ll find that, regardless of calculation method, laser alignment is for the reliability-focused plant professionals and can result in surprisingly rapid payback.

Figure 3. Effect of parallel offset on power consumption of a toroidal (tire-type) coupling at 3,000 rpm.

Last, but not least, in your reliability improvement endeavors, never let somebody’s opinion get in the way of sound science and facts. I have seen many uninformed opinions expressed in trade journals on subjects including oil mist, alignment accuracy requirments, grease application, bearing housing protector seals and one-type-serves-all lubricants. These opinions come from people with credentials ranging from junior mechanic to Ph.D and are all aimed at using unskilled labor to the maximum extent. The assumption is that this will keep cost down. In most instances, "cost" refers to contractor billing rates. I call them opinions because they don’t take into account the ramifications on component life (bearing load) and increased failure risk. They lose sight of the fact that our role is reliability improvement; cheap and sloppy work will not get us there.

Figure 4. Effect of angular misalignment on power consumption of a toroidal (tire-type) coupling at 3,000 rpm.

Self-promoting "noisemakers" with very little practical industrial experience, but with a resumé of 58 different employers in 25 years, tend to get more exposure than real field-wise experts. The reasons are many, but it's a fact that experts at major petrochemical companies have neither the time nor the incentive to write. After all, they are gainfully employed by best-of-class companies and aren’t in need of drumming up business for themselves. Moreover, their legal departments believe that sharing factual experience on the merits of using best-available technology is to be discouraged. The legal departments believe technical articles are either giving away a competitive advantage or consume time that would be put to better use in doing reliability-focused work inside the plant, or both.

Heinz P. Bloch, P.E., owns Process Machinery Consulting in West Des Moines, Iowa. Contact him at [email protected] and (515) 225-0668.