How much do you pay for an hour of actual maintenance work? The craftsman might say $20/hr. The plant manager might offer a $50/hr loaded labor rate to account for benefits, taxes, administrative costs and so forth. Communicating the relationship between loaded rates, wrench time and practical labor rates can change how executives and finance people view the maintenance organization.

The average wrench time at the vast majority of plants is between 20% and 30%. Yes, some are above 45%. A handful achieve 60%. Many are below 15%.

[pullquote]If you define practical labor rate as the average loaded rate divided by actual wrench time, you get a dramatically different answer. An average $50/hr loaded rate divided by 25% wrench time gives $200/hr for a practical labor rate. This is the cost for maintenance work that the plant’s leadership and management techniques produce.

Let’s improve wrench time by 5%. Now we get $50/hr divided by 30%, or $167/hr. Still expensive, but the 5% in wrench time saved $33/hr, a 16.5% reduction in the practical cost per hour. Purists might argue that this isn’t a valid dollar number, claiming one can never get to 100% wrench time because of time spent on lunch periods, breaks, gathering tools and parts, cleaning up, closing out jobs in maintenance software, filling out permits, etc.

That’s true, but think of it like the Lean concept in that customers don’t want to pay for waste. Most maintenance and reliability professionals agree that a figure around 65% wrench time is the highest practical value. So, if the 65% wrench time is the maximum practical labor effectiveness, the 25% wrench time represents about 38% of the practical maximum value.

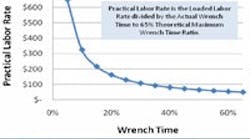

The practical labor rate is equal to the loaded labor rate (assumed to be $50/hr) times the 65% maximum wrench time divided by the plant’s measured wrench time.

Now we might be getting somewhere. A $50/hr loaded labor rate divided by the 38% yields a practical labor rate of $130/hr. Going through the same drill with the new value for practical wrench time, improving wrench time from 25% to 30% moves us from $130/hr to $108/hr (from $50/hr divided by 46%, or 30% / 65%). That is still nearly 17% improvement from a 5% increase in wrench time (see figure).

Well, enough number gibberish. How does this help a maintenance manager get what’s needed to improve wrench time? First, ask how to move from 25% to 30%, or more, wrench time. Do this by better preparing the craftsman to perform work, i.e. remove barriers to efficiency. Minimize wasted time, such as repeated trips for tools, parts, permits, etc. Put planners in place to do the prep work. Make sure you coordinate with operations and hire a scheduler to ensure your maintenance technicians always have plenty to do.

Moving from a reactive maintenance culture to a planned and scheduled culture provides the biggest benefit. Wrench time improvements of 10% to 15% are typical.

This means going from say 30% or 40% wrench time to something like 45%. But when you think in terms of wrench time, also think of the effect on practical labor rates. If you increase the wrench time from 30% to 45% for 100 maintenance techs, you don’t get just a 15% improvement.

What you get is a 50% increase in available work hours, i.e. (45% - 30%)/30% = 50%. Instead of only 30 full-time equivalents (FTE), you get 45 FTE, thereby netting 15 more people from the same 100 FTEs.

The next question concerns who must you convince. Aim for someone who can authorize organizational changes — executives, plant managers and bean counters. Greater efficiency provides the opportunity to institute six or seven planner and scheduler positions, and still have eight or nine far more effective craftsmen FTEs. All this using only the resources you already have. Trust me, you can make the case and drive practical labor rates lower.

Tom Moriarty, P.E., CMRP, is president of Alidade MER Inc. Contact him at [email protected] and (321) 773-3356.