Why do you use contractors in your facility? The list can be long and winding with reasons ranging from cost savings to acquiring specialized skill sets. Regardless of the reason, managing contractors effectively will help control costs.

The intention here is not to create guidelines for when to contract for maintenance services. Rather, it discusses how to manage those contractors once the contracting decision has been made.

Organizational decisions

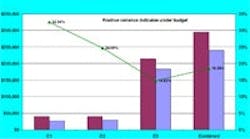

What can controlling your contractor costs do for you? The graph (Figure 1) below is a snapshot of savings generated in the first month after imposing some realistic management controls on just three contractors at a North American chemical plant. The combined savings created an 18.5% positive variance (return) worth $240,000.

What did it take to achieve these savings? Refer to Figure 2 for the decision flow. The first decision point was the role and staffing of the resident contractor — originally contracted simply to provide supplemental labor. The average daily number of personnel on site was set by contract, but the actual number was greater than the targeted amount. The numbers were reduced in increments until the overall work backlog reached the desired two to three man-weeks.

Second, all contractors were examined for the services they provided. It was determined there were too many contracting companies on site, all providing the same or similar services. Reducing the total number of companies lowered the administrative burden of managing multiple contractors.

Finally, a set of administrative controls was put into place, including control of the contractor sign-in logs, daily time sheets, progress reporting and work order management. These changes institutionalized the best practice of managing contractors through the company’s work management system.

Contractor management essentials

The example above was possible because of key decisions to implement several processes. In order to complete the first decision to reduce the number of contractors on site, each contracting company was evaluated on the following criteria:

- Safety and Environmental Compliance records

- Skills provided by the contractor

- Business volume with the plant

- Work quality

After the initial screening, the purchasing organization held discussions with the companies to determine if there were any contracting issues.

The resident contractor was notified there would be a reduction from current staffing to reach the minimum number of resident contractor personnel. After the reduction, there would be a quarterly pool ceiling evaluation based on the risk-based backlog. Because the reduction was gradual, the losses were generally absorbed by the non-resident contractors.

Because setting the administrative controls is harder, clear divisions of labor between the plant workforce, resident contractors and non-resident contractors are needed.

The following criteria should be considered for your contractor management controls.

- Define who can authorize new contractors or increase contractor staffing

- Set and mutually agree to roles and responsibilities for contractors and plant staff.

- Identify and manage contractor interfaces with the plant work management system (for example, how much access to the computerized maintenance management system will be allowed).

- Require all work done by the resident contractor to be performed under a work order.

- Require all work done by the non-resident contractors to be done under a well-defined scope of work or work order.

- Restrict the number of open or “blanket” contractor work orders — whether resident or non-resident contractors.

- Institute a formal approval process so the contracting management function can determine bid requirements when unique skill sets are needed from outside the core workforce. Example terms include:

- Time and materials

- Cost plus fixed fee

- Fixed price

- Cost plus incentive fee

- Performance-based partnership contract

- Monitor contractor performance:

- Contractor sign-in logs, daily time sheets and progress reporting.

- Contractor representative attendance at the daily and/or weekly scheduling meetings.

- Contractor quality assurance and work completion controls.

- Periodic audits of contractor job plans.

- Contractor cost management reviews for work greater than a set amount.

Roles and responsibilities of the contractor coordinator

In the previous section, criteria for managing and controlling the contractors were presented. Who makes sure that all of the carefully thought out practices, policies and procedures are followed? For plants with a minimum number of contracted services, contractor management can be an ancillary duty for the maintenance supervisor in the area. For a larger contractor presence, a contractor coordinator is a necessity.

“Best Practices” dictate that contractor resources must be managed to at least the same degree of certainty with respect to their roles and responsibilities as permanent employees. Therefore, what roles and responsibilities should be assigned to the contractor coordinator? One major North American plant defined it as follows.

The Contractor Coordinator is responsible for the activities of the contractor teams in the plant. Key responsibilities of this position include:

- Establishing expectations for safety, quality and service, including contractor records.

- Ensuring the effectiveness of the contracting effort with respect to work management; i.e., safety, planning and scheduling, workforce management, material procurement, etc.

- Communicating between contractors and the production, engineering and maintenance groups.

- Coaching contractor personnel on improving maintenance and repair techniques.

- Auditing contractor work quality and records.

- Verifying invoices.

Regardless of whether the contractor coordinator is a full-time position or a set of assigned duties, performance must be measured. There are five key areas for the coordinator. These are presented next along with suggested actions and key performance indicators (KPIs).

Safety

- Audit contractor safety meetings

- Audit contractor safety practices and housekeeping

KPIs

- Recordable Incident Rate

- Housekeeping violations

- Overdue corrective actions

Contractor Performance

- Set performance standards

- Evaluate performance

- Develop and implement performance improvement plans

KPIs

- Performance against incentive contracts

- Cost reductions attributable to contractor incentive plans, if used

Manage Contracted Workflow

- Analyze work load, determine resource requirements and assign the necessary resources (i.e. work load starts with the resident contractor and then flows to the non-resident contractors and specialty contractors)

- Review contractor backlog with the Maintenance Coordinators to determine priorities

- Audit the work in progress and assesses efficiency. Take corrective action if required

- Adjust the schedule to meet production needs

- Assure compliance to the daily schedule

- Audit completed work and assess performance

KPIs

- Backlog in crew-weeks by area and skill

- Actual vs. estimated work hours

- Contractor schedule compliance

- Causes of lost work time

Continuous Improvement

- Process contractor improvement suggestions

- Analyze contractor work efficiency and coordinate improvements

KPIs

- Percentage of rework

- Contractor cost reductions

Administrative

- Participate in developing the maintenance budget to define contracting needs

- Analyze contractor cost variances

- Manage the contracting process to add contractors in the event of emergencies

- Participate in stores inventory management (old or obsolete, repair and return, etc.)

KPIs

- Contractor actual vs. budget performance

- Contractor recommendations for cost reductions

Driving reliability savings

With the contractor management structure in place, contractor cost can be controlled and can now lead to reliability savings.

Perhaps the biggest area driving reliability savings is integrating the plant schedules of all of the organizations performing work. The integrated schedule helps avoid situations, such as one crew working overhead with another crew working below them.

[pullquote]Work delays that result from scheduling conflicts add to the cost of reliability. Delaying work adds costs of inefficiency, and other work cannot be scheduled. Work that remains unplanned or unscheduled adds an unknown level of manufacturing risk.

Integrating the schedules is easy to say but harder to do. Quite often the company’s thinking seems to be that once the work is contracted, execution is the contractor’s sole responsibility to coordinate with Production.

An effective work-management process includes daily update meetings and weekly meeting(s) focused on scheduling future work. The scheduling “window” should have at least a two-to-three week look ahead, with the schedules for next week more firm than the one three weeks out.

The daily progress meetings provide input to the next weeks’ schedules based on completion status. The weekly scheduling meeting may be either plant-wide or area-specific depending on plant size. Attendance is mandatory for the Maintenance Coordinators (Production Representatives) Planners, Maintenance Supervisors, Contractor Representatives and Contractor Coordinator. Engineering is represented if there are capital projects on the plant schedule.

A tentative schedule is provided to all parties before the meeting. One of the better ways to perform the schedule match-up is to project the work order information and tentative schedule for all to view and make comments. This is where resources are shifted to meet the schedule, crane use is coordinated,and production impact minimized.

The payoff is in two directions. First, the plant workforce is scheduled to capacity. Second, only the contractors needed are in the mill and nobody is left standing around without a scheduled week of work. If non-resident contractors have only three days of work and there are no demobilization costs, they can be sent off-site. One site business unit manager observed contractors working with, in his words, “four leaners and two workers.” His message to the contractor coordinator was to either find them work or send them home.

The reliability savings come from the work completed. A large work backlog represents risk. If the work resources are scheduled for all parties, more work can be completed and the assets are returned to service more quickly.

Contractor planning also is an area where reliability savings are possible. Having contractors plan their own routine work, however, risks overloaded jobs unless there is sufficient oversight and review of the job plans.

Contractor input to the job plans developed by the plant has substantial benefits. Often, the contractor can provide alternative methods that offer time and material savings.

Conclusion

Contractor management and controls provides cost containment and reduction in a relatively short period (see Figure 1). Contractor management and integrated scheduling reduce the cost of reliability by getting more work output for the same inputs.

William D. Conner, III, CMRP, P.E., is a senior project manager for ABB Reliability Services North America. He can be reached at [email protected] and (713) 876-9269