Looking for a job? Have you decided on a career path? Want to pursue a career that:

- Has large growth potential

- Is vital to the economy

- Has significant compensation potential

- Is challenging and satisfying

- Involves new technology

- Has high corporate visibility

- Will be experiencing high demand

Have you considered becoming a maintenance technician?

Future generations will quickly learn that our overabundant supplies of accountants, computer programmers and lawyers are driving down the wages of these professions, meanwhile, skilled labor compensation continues to rise.

|

View related content on PlantServices.com |

Despite exportation of U.S. jobs, maintenance technicians have numerous options available here. Many employers complain of a severe shortage of skilled talent. Mechanics and technicians rank No. 3 and No. 4 on the list of hardest to fill jobs, according to a 2007 manpower survey. That demand is driving up maintenance salaries. Nationwide, the average maintenance technician’s salary has grown to more than $56,000 per year. With overtime, many technicians earn close to six figures.

Companies that would love to expand are frustrated by an education system that doesn’t produce the necessary number of students with appropriate skill sets or the attitude necessary to attain needed skill sets. Many complain that our society’s view of the maintenance of yesterday hasn’t caught up with the realities of today, and as a result, business growth is stalled. With the pending retirement of so many baby boomers, that’s particularly troubling.

Despite negative perceptions, maintenance technicians are no longer just “grease monkeys” performing menial tasks. Companies now not only need technicians to perform maintenance on mechanical systems, but also electrical and electronic systems and microprocessor-based PLCs while tracking their activities using a computerized maintenance management system. Also, companies need technicians who are savvy with predictive maintenance technologies like vibration analysis, ultrasonic leak detection and infrared thermography.

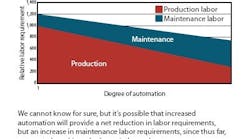

As companies continue to cut back on operators by purchasing highly sophisticated automation, these systems require more care and attention. Even if plants enjoy a net reduction in labor, they need to grow the maintenance staff to keep equipment operating at optimal levels (see figure).

Poor maintenance contributed to many of the nation’s recent disasters including the BP pipeline leaks in Prudhoe Bay, Alaska, the loss of 15 BP workers’ lives, the mass power outage of the Northeast, the Walter Reed black mold and, most recently, the salmonella outbreak in peanut butter that was determined to be caused by a leaky roof and faulty water sprinkler system. The ConAgra production facility will be closed until August to perform maintenance repairs.

With the importance of proper maintenance now hitting the headlines, to avoid bad publicity and potential lawsuits, more companies are beginning to work down chronic deferred maintenance backlogs and invest more in maintenance development. Therefore, these jobs will continue to grow in importance, stature, wages and volume.

Business and government leaders need to remember as they strive to fund bleeding-edge ideas to get cutting-edge results and competitive advantages in a global marketplace, that we also must polish the rusty edge of business. In other words, we can’t forget to perform proper maintenance of the hydraulic, electronic and electrical systems that sustain us today, as we strive to develop biotech and nanotech solutions for tomorrow.

Nowadays, just to keep up with the advances and changes in the economy, you have to be pretty smart to be smarter than a professional maintenance technician.

Contact Contributing Editor Joel Leonard at [email protected].